|

Policy Perspective: Resource

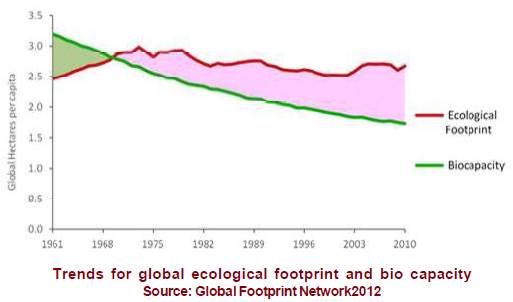

Efficiency W hy do we need Resource Efficiency?The maxim for growth since the 20th century has been ‘MORE’, thus bringing emphasis on increasing efficiency by deriving more from what is on hand; exploring how far we can stretch available time, cost, effort. This thrust for ‘MORE’ drove the Industrial Age and is the soul of the current Information Age. Realising how far we have exhausted our existing resources – globally we are already operating at over 50% of our bio capacity - Resource Efficiency has earned a spotlight in global sustainability dialogues.

For India, this overshoot stands at 1.8 times the 0.5 gha/cap biocapacity with the 0.9 gha/cap ecological footprint as of 2010. Estimates of India’s future material demand under different scenarios, range from 17 billion tonnes to 47 billion tonnes (IGEP, 2013). With the year on year increase in the biocapacity

deficit, the imprudence of continuing in a business as usual (BAU)

manner cannot be over emphasised. We are, as is often quoted, already

‘living on the capital of the planet rather than its income’. If we

continue operating BAU, it is estimated that by 2030, we

The challenges of such resource consumption and its impacts are incessantly increasing due to a growing population (estimated to be over 9 billion by 2050) with a burgeoning middle class, rapid urbanisation and expansion of the production and service sector (DA-Wuppertal, 2014).This translates into an urgent call to decouple our economic growth from resource use, reduce ecological footprints and promote greater sustainability for individuals, businesses and countries. What exactly is Resource Efficiency? UNEP’s International Resource Panel(IRP) has done revolutionary work on resources and resource efficiency. IRP defines resources as natural resources used by economies such as abiotic materials (fossil fuels, metals and minerals), biomass, water and land. Resource efficiency is using less resource inputs to achieve the same or improved output; expounding the relationship between a valuable outcome and input of natural resources required to achieve it. It indicates the effectiveness with which resources are used by individuals, companies, sectors and economies. Resource efficiency can be achieved by increasing productivity or reducing intensity. Resource productivity describes economic gains achieved through resource efficiency as the value obtained from a certain amount of natural resources. Total resource productivity is calculated as Gross Domestic Product / Total Material Requirement. Resource intensity, the inverse of resource productivity, depicts the amount of natural resources used to produce a certain amount of value or physical output. It is calculated as resource use / value added or as resource use / physical output. Thus in effect, resource efficiency is a way to deliver more with fewer resources thus minimising environmental impacts. It increases value through more productive, sustainable use of resources, while adopting a life cycle approach. The World Business Council for Sustainable Development estimates that by 2050 we will need a 4 to 10 fold increase in resource efficiency, with significant improvements needed already by 2020. How is Resource Efficiency relevant to the Construction Sector? The potential to use resources more efficiently is vast, once we identify hot spots and priority areas for change. In the Indian context also, construction, industry (especially manufacturing and power generation) and agriculture are energy and resource intensive sectors. These findings are supported by other studies listing construction, agriculture, and food and beverages as main material consuming sectors (SERI et al. 2009, BIS 2010, DA-Wuppertal, 2014). Construction has exhibited an upward trend in resource use. In the 20th century, the global extraction of construction minerals increased by a factor of 34, significantly outpacing a quadrupling of world population and a 24-fold increase in GDP. In a catch up scenario as needed in developing countries, this translates to tripling the annual resource use (UNEP, 2011). In 2011–2012, India’s construction sector accounted for 8.2% of the country’s GDP employing 41 million people. Poised to become the world’s third largest construction sector by 2018, the sector is expected to grow by 16-17% over the next ten years. The construction and use of buildings driven by rapid urban expansion is likely to impose tremendous pressures on the natural resources. Environmental impacts such as land degradation, waste generation and CO2 emissions from transportation and production are closely proportional to the volume of extraction and use of resources. The construction sector accounts for 30% of electricity consumption in India, growing at 8% a year and 23.6% of the national greenhouse gas (GHG) emissions (Parikh et al. 2009). Material resources account for 80% of these emissions. The consequent pressures exerted on natural resources result in increasing resource scarcity as well as escalating costs of construction. Low-cost, local, low-embodied energy and resource efficient materials and technologies exist, that can help mitigate this pressure. However there is limited spontaneous adoption of these resource efficient options, beyond isolated oasis of good practices. In order to scale up such initiatives, it is important to create an ecosystem where eco-friendly materials, technology and expertise are available and accessible to all. While many policies at the national level promote sustainability in construction, resource efficiency is not dealt with as a major driver for the economy and its sectors. How can India move towards Resource Efficiency? The European experience, possibly the pioneering one under resource efficiency highlights that the transition to a resource-efficient and low-carbon economy needs to be supported by: • Coordinated policy action across sectors in a systemic manner with political visibility and support• Effective, accessible and flexible investment opportunities that will have short term benefits in job creation and long term benefits for the overall economy• Persuasive messages empowering consumers to move to resource-efficient consumption, driving continuous innovation so efficiency gains are not lostThe current trend of emulating western growth patterns will come at a very high resource price. Existing markets and policies are ill-equipped to deal with competing demands on strategic resources such as soil, sand, minerals, etc. This calls for a coherent and integrated policy and action framework to provide a stable perspective for transforming the economy (EC, 2011). The Indian construction sector epitomizes resonance for this policy imperative assimilating the triad of technology, finance and capacity. Policy and regulation lay down the framework and roadmaps for change. Change needs to be effected in terms of • Research and innovation on enhancing resource efficiency of construction technology needs an impetus, learning from vernacular and indigenous practices and integrating scientific advances e.g. bio-mimicry, use of industrial and demolition wastes, green building certification, smart homes, etc.• Capacity Building of end users to influence behaviour change to adopt resource efficient measures is crucial. Technical capacities and skills of facilitators and intermediaries like masons, material providers, designers, planners, engineers, etc. need to be strengthened to provide a robust supply chain.• Diffusion of green technologies and expertise is impeded by financing. Channelising investments and financial incentives are needed to strengthen the supply chain. There is a need to bring together technical and financial experts in order to develop innovative financing schemes. qKriti Nagrath References BIS (Department for Business & Innovation Skills) (2010). Potential for resource efficiency savings for businesses. Development Alternatives-Wuppertal (2014) Decoupling Growth From Resource Consumption Background Paper 2nd Indo-German Expert Group Meeting on Green and Inclusive Economy European Commission (2011).Communication From The Commission To The European Parliament, The Council, The European Economic And Social Committee And The Committee Of The Regions - A Resource-Efficient Europe – Flagship Initiative Under The Europe 2020 Strategy Indo German Environment Program (IGEP) (2013) India’s Future Needs for Resources National Footprint Accounts (2010) www.footprintnetwork.org.Extracted on October 13, 2010 Parikh et al. (2009). CO2 emissions structure of Indian economy Sustainable Europe Research Institute (SERI), Global 2000, Friends of the Earth Europe (2009). Overconsumption? Our use of the world´s natural resources. Vienna/Brussels Sustainable Europe Research Institute (SERI) (2012) Material Flow Database UNEP (2011) Decoupling natural resource use and environmental impacts from economic growth, A Report of the Working Group on Decoupling to the International Resource Panel. WWF’s Living Planet Report 2012

|

Worldwide, the human ecological footprint is 2.7

global hectares per capita (gha/cap) compared to a worldwide biocapacity

of only 1.8 gha/cap (National Footprint Accounts 2010). This overshoot

or biocapacity deficit means that we are already using 1.5 times the

resources that are available to us. This can be exemplified through the

jump in global material use from 35 billion tonnes in 1980 to nearly 68

billion tonnes in 2009 (SERI, 2012).

Worldwide, the human ecological footprint is 2.7

global hectares per capita (gha/cap) compared to a worldwide biocapacity

of only 1.8 gha/cap (National Footprint Accounts 2010). This overshoot

or biocapacity deficit means that we are already using 1.5 times the

resources that are available to us. This can be exemplified through the

jump in global material use from 35 billion tonnes in 1980 to nearly 68

billion tonnes in 2009 (SERI, 2012). will need

resources equivalent of two planets to sustain ourselves (WWF’s Living

Planet Report 2012).

will need

resources equivalent of two planets to sustain ourselves (WWF’s Living

Planet Report 2012).