|

Limestone Calcined Clay Cement – T he construction sector is one of the fastest growing sectors in India contributing to 22% of the total CO2 emission in India. India is one of the largest cement producers in the world. The country has an installed capacity of 300 million tonnes (2011) which is slated to rise to 600 million tonnes by 2020. Since the production of clinker relies largely on limestone, it produces around 137 million tonnes of carbon dioxide (as of 2010) which is approximately 7% of the total man made CO2 emissions of the country. Apart from environmental emissions, the industry also uses quite a substantial amount of natural resources, majority of which are in form of limestone and coal.The resources for making cement are finite.

Increasing depletion of naturally resourced raw materials will affect

the production of cement in the future. To optimise the use of natural

resources, supplementary cementitous materials (SCM’s) are a viable

alternative. India uses a substantial amount of fly ash as SCM’s.

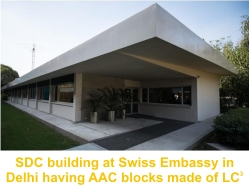

However, the substitution of fly ash is limited to 30%. Limestone Calcined Clay Cement or LC3 is a

new type of composite cement based on a blend of clinker, calcined clay

and raw limestone. Clinker content is as low as 50%. LC3

technology has several advantages over Ordinary Portland Cement (OPC)

and Portland Pozzolanic Cement (PPC) such as: LC3 has a high chloride penetration resistance and produces a dense microstructure with high resistivity which makes it very suitable in corrosive atmospheres like the marine environment. As the requirement of calcination temperature of china clay is lower than clinkerisation by 500ºC to 600ºC, so a significant thermal energy is saved for LC3 production compared to OPC. Even at the locations with shortage of high quality fly ash, production of LC3 is more economical than PPC. LC3 can be produced using low grade china clay which is in abundant quantity in India. Even in several cases, the quality of the clay rejected by clay industries is well accepted for LC3 production. Hence, it gives another dimension towards utilisation of the wastes and efficient resource management. 200 tonnes of LC3 has been produced in India so far. A detailed study and assessment are in progress to understand all aspects of the cement. Various building materials like micro concrete roofing tiles, pavers, kerb stones, hollow concrete blocks etc. have been produced in pilot scale using LC3. ■ Palas Kumar Haldar References: 2. Existing and Potential Technologies for Carbon Emissions Reductions in the Indian Cement Industry: Cement sustainability initiative, world business council for sustainable development (2012) 3. Technology Roadmap, Low Carbon Technology for the Indian Cement Industry: World business Council for sustainable development (2012) |