|

How a Rating System is Improving A Fly Ash Brick Quality Rating System (FABQRS) was formulated and implemented in Bihar to effectively address the quality issues of fly ash bricks in the state. The objective of this system is to provide acceptable quality criteria for the production of fly ash bricks across the state. A pilot programme was designed to demonstrate the utility and effectiveness of FABQRS. Development Alternatives (DA) acted as the certifying agency responsible for implementing the proposed FABQRS, by identifying, assessing and certifying fly ash brick enterprises as class A, B, C and D, based on four quality parameters: compressive strength, water absorption, efflorescence and dimensional tolerance. Benefits for Entrepreneurs Enrolling in FABQRS

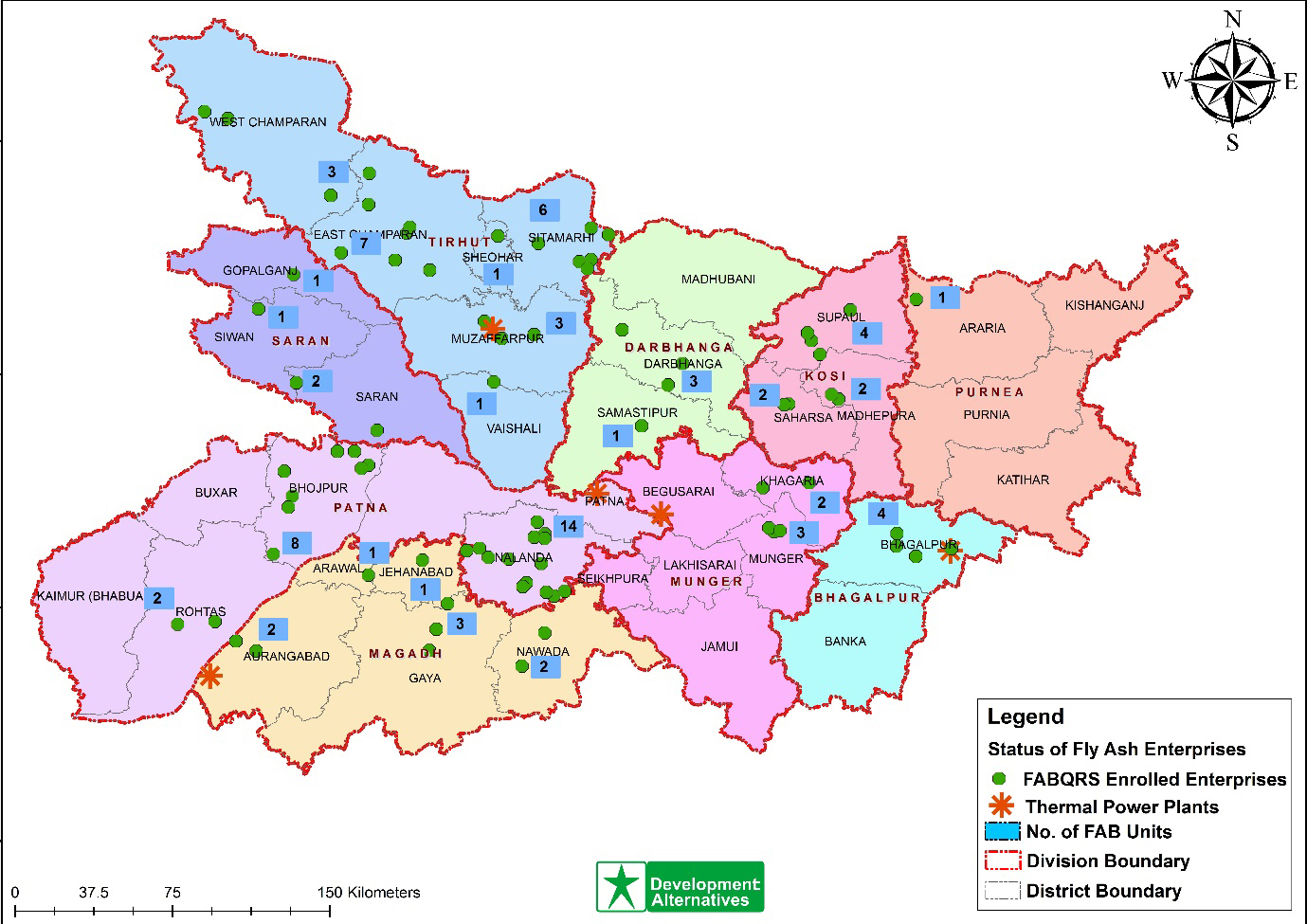

By August 2020, FABQRS was successfully demonstrated across the 23 districts of Bihar where a total of 80 enterprises were evaluated thus far. Since August 2019, 50 new enterprises have been enrolled under the system (See Map). The first round of sampling has been done for all new enrolled enterprises and testing and reporting has been done for 35 enterprises so far. Based on the test results as per FABQRS and BIS 12894:2002, grading was done and it is found that some entrepreneurs are making good quality of products but most are not making the required quality. Assessment and onsite training were provided by the DA team to all 35 enterprises and it was found that entrepreneurs lacked information on the following:

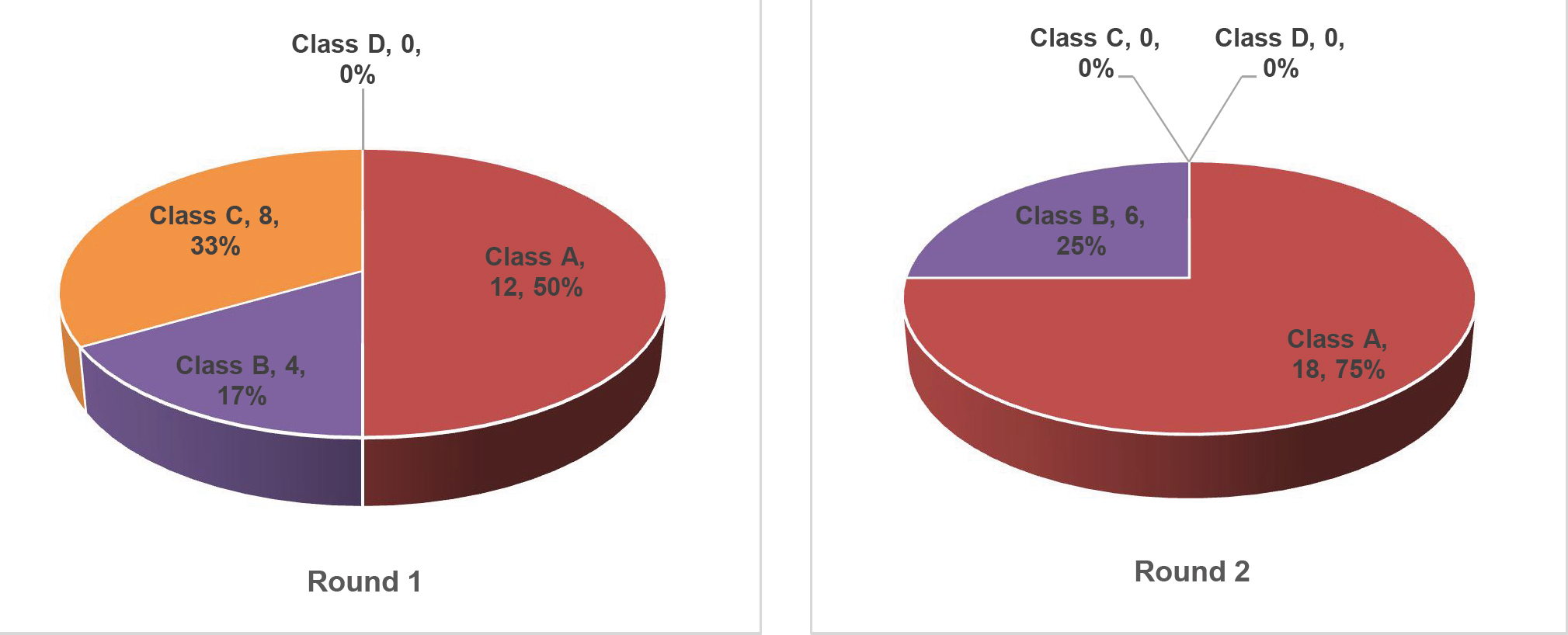

FABQRS Impact Across the 23 districts of Bihar where FABQRS was demonstrated, evaluation was carried out for 24 enterprises, and it was in progress for the rest. After a thorough analysis of various challenges faced by fly ash brick entrepreneurs, support was provided for enhanced brick quality. The impact of this programme can be seen through the improvement in brick quality for 11 enterprises, and maintenance of quality for the others. This result highlights the overall success of the FABQRS programme, as evident from Graph 1 depicting the transition of enterprises from lower (C and B) to higher (B and A) quality rating. ■

Graph 1: Impact of FABQRS

References

Avinash Kumar

|