Brick by Brick - Enhancing

Fly Ash Brick

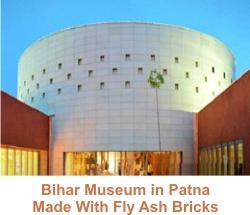

Use in Bihar

Clay Brick Domination

The brick sector in Bihar is dominated by fired clay bricks. These bricks have a traditional perception of quality and durability. However, the age-old practice of manufacturing clay bricks has now become detrimental to productive land and air because of surge in the demand. Bihar has 6,000 polluting Fixed Chimney Kilns (FCKs) which use 2-4 million tonnes of coal annually and emit 4-6 million tonnes of carbon-dioxide (CO2). Clay bricks utilise 30 million cubic metres of top soil every year which crops up issues of food security in the state. The use of clay bricks can be reduced by shifting to fly ash bricks. Availability of fly ash in the state is not a concern as there are four coal-based thermal power plants in the state which generate millions of tonnes of fly ash every year.

Fly Ash Brick Potential

Bihar's fly ash brick sector has grown considerably since 2006. Currently,

there are more than 100 fly ash units in Bihar with an annual production

capacity of 60 million bricks. This is an increase of 32% from 2013. In

hindsight, fly ash bricks have a lot of ground to cover to reduce clay brick

use in Bihar. For example, N.T.P.C Kehelgaon a thermal power station in

Bihar generates about 4 million tonnes of fly ash per year. This fly ash can

be used to potentially produce about 3000 million fly ash bricks.1 The

current fly ash brick production capacity is just 2% of this potential.

There is definitely a need to increase the fly ash production and

utilisation in Bihar.

Challenges Ahead

Further proliferation of this technology is hampered by several factors like the lack of market demand, perception of poor quality of bricks, raw material fluctuations and lack of access to finance. These issues also hinder the operation of current units. Some of these challenges are explained below:

a. Perception of Poor Quality of Bricks

A negative and false mindset is prevalent among the consumers regarding the poor quality of fly ash bricks. There is no assurance system in place to ensure quality of fly ash bricks as per the BIS standard. The lack of any kind of quality check and assurance mechanism leads to sub-standard bricks flooding the market and the entire technology acquiring a bad name.

b. Lack of Market Demand

The market demand is largely governed by price, quality and on time availability. The demand is also influenced by awareness. Though the price of fly ash bricks are included in the State Schedule of Rates (SoR), on time availability and quality is hampering government projects to procure fly ash bricks. Many big builders and also small contractors who build individual homes are not aware of availability of fly ash bricks in the region. Hence the market demand has not proliferated in Bihar.

c. Lack of Access to Finance

The fly ash bricks business is not yet recognised as a credit worthy industry by the banks as not many fly ash brick units have demonstrated steady profits. The existing fly ash units do a lot of credit business with big builders and do not get payment on time hence are unable to repay the loans. Subsidies to set up new enterprises are also provided to the entrepreneurs by the Department of Industries however delays in approvals discourage entrepreneurs from applying.

d. Raw Material Fluctuation

Fly ash bricks are fabricated using fly ash, cement and sand. Sand is one of the most sensitive materials in Bihar in terms of availability due to regulatory bans. Due to availability issues, price fluctuates a lot which is reflected in the market price of fly ash to the consumer.

Solutions

The challenges can be addressed by putting in place certain mechanisms. Following are some of these mechanisms:

-

A fly ash brick quality rating system should be developed by an independent agency and fly ash bricks should be labelled based on their quality. This will put in place quality assurance for fly ash bricks.

-

Capacity building and supporting existing and interested entrepreneurs for enhancing quality and setting up fly ash brick units.

-

Notification of preferential procurement of fly ash bricks for government projects. This will help create market for fly ash enterprises.

-

Continuous awareness of fly ash bricks to win the perception of user. ■

Endnote

1Considering 1.5 Kg of fly ash per brick

Vaibhav Rathi

vrathi@devalt.org