The Global Perspective

From The time of "Green Revolution" to the " Industrial Revolution" it has become evident that in order to improve the existing practices, the whole world has to unite and act together in order to bring about a significant change. With the increase in pollution and unending environmental degradation, it is once again becoming imperative to bring about yet another revolution: The Clean Revolution. It is very important to understand the power of technological innovations and information dissemination - the two main tools of change. It is high time that all countries come forward for experience-sharing whether it is in the form of AIJ (Activities Implemented Jointly) or other projects of North-South Collaboration, leading to technology transfer, action research, management and large scale dissemination of improved practices.

The Indian Picture

In India, there is an acute housing shortage and a perceptible shift towards energy intensive materials like cement, steel, aluminium and PVC. The rate of growth of housing activity has increased considerably in the past two decades (as compared to the earlier decades). A growth rate of 25.08% in rural areas and 42.33% in urban areas was computed in 1981-91, which translates to 2.34% and 3.89% annual growth rate in rural and urban areas, respectively.

It is important to realize that at

present the construction sector alone accounts for 22% of Carbon dioxide

emissions in the country and already consumes a disproportionately large share

of non-renewable energy. Future generations will face insurmountable

environmental problems unless technological corrections are made and applied. Sustainable

building technologies and materials is the path along which we, as a nation

and perhaps the whole world, must travel. As a step in that direction, this

article is an attempt to create awareness about the existing technological

innovations taking

It is important to realize that at

present the construction sector alone accounts for 22% of Carbon dioxide

emissions in the country and already consumes a disproportionately large share

of non-renewable energy. Future generations will face insurmountable

environmental problems unless technological corrections are made and applied. Sustainable

building technologies and materials is the path along which we, as a nation

and perhaps the whole world, must travel. As a step in that direction, this

article is an attempt to create awareness about the existing technological

innovations takingplace in India.

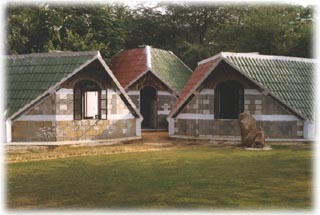

The focus here is on a sloping roof option - Micro Concrete Roofing (MCR) Technology. It may not be an ideal option for mega cities, where space / land is a constraint and hence flat roofing is required, but in rural areas, peri-urban areas and small towns this technology can fill in the gap between kachha, and more expensive pucca roofing options. Other choices available in plains such as Asbestos Cement Concrete (ACC) sheets, Galvanised Iron (GI) Sheets and clay tiles, have a set of problems. For example, ACC sheets have a major carcinogenic effect on both the user and the producer; GI sheets are manufactured in large centralised industrial units due to which they have to be transported long distances while clay tiles are highly energy- intensive and lack quality. On the other hand, Micro Concrete Roofing is a more durable, cost effective and environment-friendly option which can meet the growing aspirations of the people.

The Technology

Micro Concrete Roofing Technology came to the fore in England, while development of the complete technology package was a result of global R&D.

In India, Development Alternatives, has developed and adopted the technology and is actively promoting it since 1996, in active collaboration with SKAT (Swiss Centre For Development Cooperation in Technology Management) and SDC (Swiss Agency For Development Cooperation).

MCR tile is an internationally accepted product. Globally, MCR is promoted in 55 countries spanning Latin America, South Asia and Europe. In India, there are over 220 operational enterprises spread over different parts of the country, and the numbers are growing. Apart from being a sound technology, MCR has also proven to be a good business option for small and medium scale entrepreneurs.

The Product

MCR tile is an energy efficient, eco-friendly product made from a carefully controlled mix of cement, sand, fine stone aggregate and water. These tiles can be made in two distinct profiles - Pan and Roman. They can be installed on a wide variety of under-structures e.g. steel, primary and secondary wood. MCR tiles could also be produced in an infinite range of colours.

The Technology Package

The technology package for MCR is the result of rigorous action research by Development Alternatives, as in order to make the technology and product sustainable and optimum, many rounds of iteration were done. There was a set of ecological, social, technological and financial aspects, to which the technology had to comply with in order to be classified as a Sustainable Building Technology ready for large-scale dissemination. The technology package consists of:

Hardware

A vibrating table, operated by an electrical motor, with the rating of ¼ HP @ 2800 rpm.

A set of injection moulded HIPS mould, mounted on wooden frames.

A complete set of accessories and quality control material.

An alignment tool for checking the shape and size of each tile.

A bending test equipment for monitoring the tile-strength.

User’s manual.

Software

Training/ construction manual for operation

Techno–economic feasibility report customized for different scales of operation.

On-job training for production and installation of tiles on roof.

Standard promotion tools for marketing of tiles.

Structural design support for roof.

Facilities and Production Process

The production system is enterprise oriented - micro to medium - depending on the number of MCR tables in operation. One would require between 15 to 30 Lakh rupees of capital investment, depending on the scale of business. The returns on the entrepreneur’s investment in these cases range from 56% to 144%. For making 15,000 tiles per month (equivalent to 1200 sq. m. of roofing), 300 cement bags, 15 cu. m. of sand and 7 cu. m. of aggregate are required. For operating the system, three skilled and 10 semi-skilled operators are required on the working floor.

An MCR workshop needs a compact infrastructure for a three-table

operation that could be housed in a 60 sq. m. shed. While the total area

required is 1000 sq. m. for raw material storage, curing tanks and a finished

stock-yard, a 7.5 KVa power connection for electrical purposes and 3000 litres

of water-supply is also required. The tiles can be manufactured at one location

and transported from there while in the case of large building projects, the

equipment can be moved for on site manufacturing of tiles. For making MCR tiles,

a controlled mix of cement, sand and fine aggregate and water is vibrated at a

frequency of 45 seconds on a precision-engineered TARA table vibrator /

screeding table. It is then transported to High Impact Polystyrene moulds that

provide the MCR tiles their unique profile. After the initial setting in an

air-tight environment for 24 hours, the tiles are cured in water for a period of

7 days. This process gives the MCR tiles their unmatched strength and

durability.

An MCR workshop needs a compact infrastructure for a three-table

operation that could be housed in a 60 sq. m. shed. While the total area

required is 1000 sq. m. for raw material storage, curing tanks and a finished

stock-yard, a 7.5 KVa power connection for electrical purposes and 3000 litres

of water-supply is also required. The tiles can be manufactured at one location

and transported from there while in the case of large building projects, the

equipment can be moved for on site manufacturing of tiles. For making MCR tiles,

a controlled mix of cement, sand and fine aggregate and water is vibrated at a

frequency of 45 seconds on a precision-engineered TARA table vibrator /

screeding table. It is then transported to High Impact Polystyrene moulds that

provide the MCR tiles their unique profile. After the initial setting in an

air-tight environment for 24 hours, the tiles are cured in water for a period of

7 days. This process gives the MCR tiles their unmatched strength and

durability.Technical Data (Standard Pan Tiles)

Clear length 488 mm

Length after overlap 400 mm

Clear width of tile 240 mm

Width after overlap 200 mm

Thickness 8–12 mm

Corrugated depth 50 mm

Nominal weight 2.25 kg

Load bearing 80 kg/sq. cm.

capacity of tile

The MCR tile has been validated and certified by BMTPC (Building Materials and Technology Promotion Council), Ministry Of Urban Development, Government of India.

The Cutting Edge

Cost Effective: As the tiles can be made on site or in the near vicinity, the cost of transportation is bare minimum. Being light in weight, they require a lighter under-structure, thus saving on costs.

Durable: Their life span is same as that of concrete. In performance also, they are water-proof and fire resistant.

Aesthetic: Can be coloured as per specification and laid out in different patterns.

Environment-friendly and energy-efficient: The technology does not use harmful or energy-intensive raw materials and saves precious fuel as it does not require baking.

Social benefits: The scale of the business is such that it helps to create jobs in the location of the enterprise (per operating table, as 4 -5 direct jobs are created). It is not a gender-biased technology, thus women can operate an enterprise with equal ease as men.

Local economy component: As the production system is decentralized enterprise based, the local economy of the construction location is benefited and strengthened.

Utilisation of industrial waste: Industrial wastes, which are otherwise a health hazard, such as stone dust / fly ash, could be utilised as raw material. (R&D for this is in progress)

Construction Details

The construction process is fairly simple. Depending upon the climate and span, the options available are lean-to roofs, gable roofs, north light trusses and hipped roofs. The ideal angle of slope should be between 18-220 for dry areas and 22-260 for heavy rainfall areas. The optimum overhang should be about 600mm for protecting the walls. The MCR tiles are secured to purlins with the help of a GI wire, while the purlins rest on rafters. There is a wide variety of under-structure material available, namely primary and secondary timber, steel trusses, wire girders and bamboo.

Application

It is an ideal option for rural, peri-urban and urban areas. Due to its aesthetic appeal, simplicity of form and variety of colours and design possibilities, it has been widely used in residential, commercial and institutional buildings. Due to universality of the raw materials, it is also ideal for all kinds of climates including high rainfall areas.

Clean Technologies

Clean technologies like MCR are a model for development and dissemination of other Sustainable Alternative Building Technologies, which can help augment the supply of building materials to meet the aspirations and growing purchasing power of the society, while not causing any damage to the already vulnerable environment. Development Alternatives has been rigorously developing marketing strategies, using franchising model and technology promoter network, for faster penetration in Indian markets. It is becoming evident that sustainable building technologies such as the MCR technology, which is sensitive to the people, resources and environment, are the need of the day.

Other Technology Profiles under the Sustainable Building Technology series are: