|

Vertical Shaft Brick Kiln

-

gearing for cleaning the environment in the brick sector Millions of dollars are spent in the form of grants, subsidies and loans to make

this earth a cleaner place. But are the present cleaner options – easily available, more efficient, cost effective, technologically successful and most important, accepted by the society at large? Keeping

these questions in mind, a new initiative "India Brick Project" was

supported by the Swiss Agency for Development and Cooperation and

implemented by Development Alternatives, TERI, Gram Vikas and Damle

Clay Structurals Pvt. Ltd. was launched. The major stakeholders

including brick entrepreneurs, policy makers and regional industry

associations agree that the Vertical Shaft Brick Kiln Technology is

a highly viable and appropriate solution for Indian conditions. Policy Support Policy

support has been forthcoming from the Central Pollution Control

Board (CPCB). The Central Board is preparing to issue draft

notification for Emission standards and stack height regulation

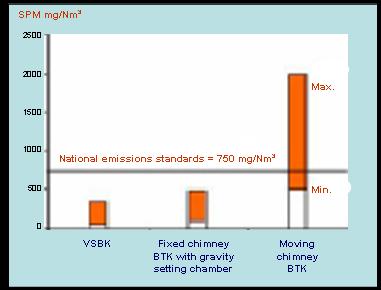

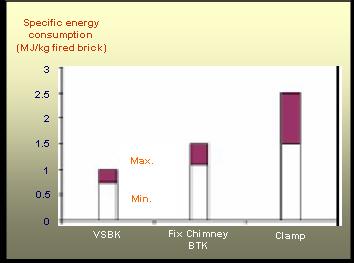

for the Vertical Shaft Brick Kilns. In their opinion, the

Vertical Shaft Brick Kilns are energy efficient with low emission

levels and do not require high stacks unlike BTKs. Most recently,

the Central Board has recommended to the state Pollution Control

Board and PCCs to promote VSBK technology for brick making. Capital Financing Brick industry has two profiles of entrepreneurs.

The financing options available to medium scale entrepreneurs are indeed limited as majority of finance is needed for working capital. Banks and financing institutions shy away from providing finance as there are no tangible fixed assets and the traditional brick business is susceptible to vagaries of weather VSBK requires almost 20 times lesser time and investment as compared to clamps and BTKs. Risk for offering credit to VSBK is further reduced as kiln itself act as permanent fixed investment and can be used as collateral security. The pulse of increasing confidence among bankers can be easily assessed from the fact that a loan was sanctioned from ‘Oriental Bank’ Shivpuri (M.P) to a women entrepreneur in short time of just 8 days. Currently more than 6 entrepreneurs have taken loan from bank under KVIC margin money scheme. From the

point of view of banks and financial institutions, Development

Alternatives is working towards achieving better technological

performance with higher level of appropriate mechanization. This

will benefit the entrepreneurs in terms of arranging financing for

capital investments. At present, the capital expenditure is on

account of mechanized lifting, lifting screw and trolley

arrangement, pugging mill and brick extruder.

Production Flexibility VSBK

gives a unique flexibility in brick production where one can easily

change his productivity by decreasing or increasing the operations

at its shafts. Labour Friendly VSBK offer a conducive environment for the brick workers to work an almost smokeless and dust free environment. With this perspective in mind DA with its sisters concern TARA is preparing a roll out plan to establish large number of kilns in coming five years in Bihar, M.P, U.P., Rajasthan, Orissa, Chattisgarh and Raipur. The details will be shared in the forthcoming issue. q |