|

Geopolymers: An Approach

towards

Building

materials are always in demand in the construction sector, especially in

developing countries. To reduce our dependency on virgin materials,

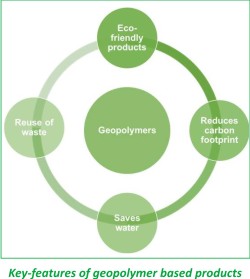

researchers are developing resource efficient building materials. Geopolymer is one such emerging approach towards green building

materials. Geopolymer is an amorphous, 3-D inorganic polymer formed when

a highly concentrated aqueous alkali hydroxide-silicate solution is

added to an alumino

Kiran Global Chems Ltd., a Chennai based

company adopted the geopolymer technology developed by Professor J Davidovits. Kiran Global Chems, started in 1979 as a chemical

manufacturing company. It currently produces geocement, geopolymer

activator, geopolymer powder, geopolymer concrete and geopolymer

concrete blocks. The company believes in environmental protection, a

sustainable future and a green building concept. Their most recent

initiative is to utilise waste for manufacturing green cement called

geocement. Th Way Forward With the amount of industrial wastes including boiler ash, slag, fly ash, pond ash and construction and demolition (C&D) waste generated in India, the sector needs a push to adapt technologies and practices focused on ‘waste to wealth’. Kiran Global Chems. is an initiative in this direction and many such replications in the country are needed to reduce our dependency on virgin materials.

References: • Bagci, C., Kutyla, GP., Kriven, WM (2017) Fully reacted high strength geopolymer made with diatomite as a fumed silica alternative, Ceramics International, 43, 14784-14790 • Davidovits, J., 2011. Geopolymer Chemistry and Applications, third ed. Institut Geopolymere, Saint-Quentin, France. • Singh, B., Ishwarya, G., Gupta, M., Bhattacharyya, SK. (2015) Geopolymer concrete: a review of some recent developments, Construction and Building Materials, 85, 78-90 • Sudhakar, MR and Indra Prasad Acharya, IP. (2014) Synthesis and Characterization of Fly Ash Geopolymer Sand. Journal of Materials in Civil Engineering, 26, 5. ■

Dr. Ankur Sarswat

|

silicate raw material such as slag, fly ash, calcined

clay etc. (Davidovits, 2011). Being energy efficient and eco-friendly,

geopolymers are gaining attention. During production, geopolymers

release 80% less CO2 than Portland cement. They exhibit

attractive characteristics including high compressive strength, low

shrinkage, fast setting, acid and fire resistance, low thermal conductivity etc (Bagci

et al., 2017). Some recent examples on geopolymers include manufacturing

artificial sand by geopolymerising fly ash, diatomite based geopolymers

etc (Bagci et al., 2017). The material thus obtained is highly stable,

chemical resistant, hard and adheres to different surfaces (Singh,

2015). Geopolymers are alternative binders to Portland cement (OPC)

while producing mortars and concrete (Sudhakar, 2014). Replacing OPC

with geopolymers favours low energy consumption and more carbon savings

(Sudhakar, 2014).

silicate raw material such as slag, fly ash, calcined

clay etc. (Davidovits, 2011). Being energy efficient and eco-friendly,

geopolymers are gaining attention. During production, geopolymers

release 80% less CO2 than Portland cement. They exhibit

attractive characteristics including high compressive strength, low

shrinkage, fast setting, acid and fire resistance, low thermal conductivity etc (Bagci

et al., 2017). Some recent examples on geopolymers include manufacturing

artificial sand by geopolymerising fly ash, diatomite based geopolymers

etc (Bagci et al., 2017). The material thus obtained is highly stable,

chemical resistant, hard and adheres to different surfaces (Singh,

2015). Geopolymers are alternative binders to Portland cement (OPC)

while producing mortars and concrete (Sudhakar, 2014). Replacing OPC

with geopolymers favours low energy consumption and more carbon savings

(Sudhakar, 2014).  is geocement is blended with bye-product materials such as

fly ash, rice husk ash, slag, activated clay, alumina to form a concrete

for quick setting (150 minutes). This type of producs can be very useful

in repairing of flyovers or roads that carry heavy traffic load and

cannot be blocked for several hours. The company demonstrated use of

geopolymers based paver blocks for a pathway.

is geocement is blended with bye-product materials such as

fly ash, rice husk ash, slag, activated clay, alumina to form a concrete

for quick setting (150 minutes). This type of producs can be very useful

in repairing of flyovers or roads that carry heavy traffic load and

cannot be blocked for several hours. The company demonstrated use of

geopolymers based paver blocks for a pathway.