|

A Cluster Approach To

Sustaining

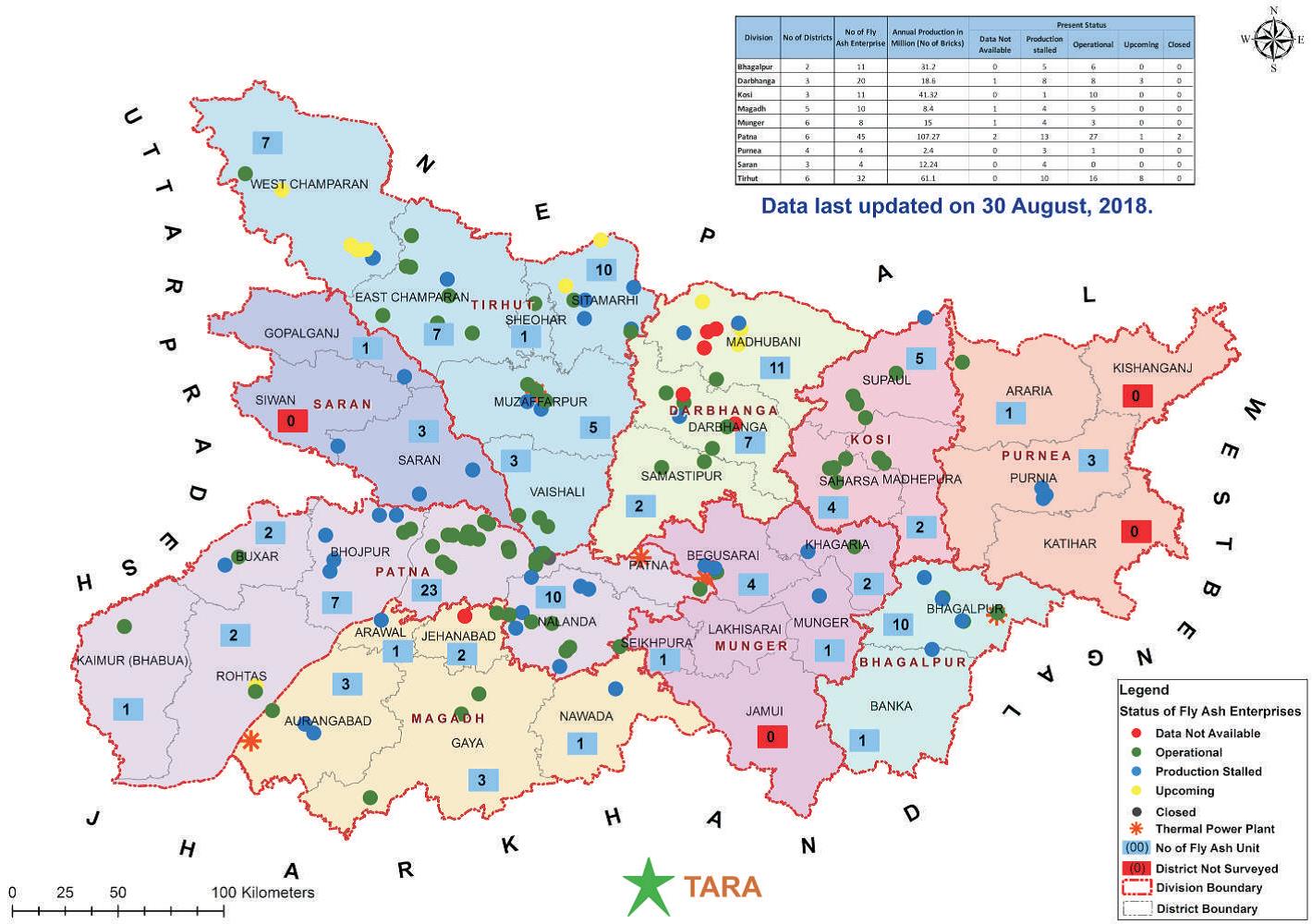

Bihar is one of the fastest growing states in India. Propelled by its economic and population growth, it is witnessing a boom in its construction sector, and there is increasing demand of bricks as a major building material. Bihar has about 7,700 clay brick kilns1 with an annual production of approximately 23 billion bricks2, and holds the largest production share of about 97% in the state’s brick industry. The clay brick industry currently is based on a decentralised production activity using energy intensive, resource depleting and highly polluting technologies and production methods. The sector provides seasonal employment to large number of labourers, but the production process involves use of fertile soil, which is in direct conflict with the agricultural sector. Curbing this challenge is essentially crucial for Bihar being an agricultural economy. For the state of Bihar to ensure that the state’s economic growth is not at the cost of environmental and public health, it is extremely important to take initiatives to promote cleaner brick technologies and waste management. In the given situation, encouraging the production and usage of fly ash bricks in Bihar is an opportunity for transition towards resource efficient bricks while providing decent jobs to the local community. Fly ash bricks are very resource efficient, least energy intensive and much greener alternates to other types of bricks. In comparison to burnt clay bricks, each fly ash brick conserves 3kg of top soil, 0.024kg of coal, and mitigates 0.077kg of CO2 emissions. The social, economic and environmental benefits of fly ash bricks are immense. However, the fly ash brick industry in Bihar has been struggling to gain a fair share of market in the state’s brick industry. The industry is plagued by various challenges that have become barriers to its upscaling. These challenges are majorly related to timely availability and quality of raw material, awareness about fly ash brick among the general public, ease of access to finance and technology know-how, enforcement of government policies and competitiveness. Moreover, most of these enterprises work and suffer in individuality, lacking vision and collective action plan to uplift the industry. Given the importance and urgent need of resource efficient green building materials like fly ash brick, a cluster-based approach for sustainability of fly ash brick enterprises is a must. The Development Alternatives (DA) Group has been implementing measures under its cluster development approach to promote and sustain Fly Ash Brick (FAB) enterprises in Bihar. DA’s methodology broadly includes identification of potential FAB clusters, selection, diagnostic study, action plan, implementation and monitoring and evaluation (M&E). Stakeholder management for trust building and M&E form an integral part of the cluster development process from ideation to successful implementation. Demand versus availability of FAB has been a topic of constant debate in various state level meetings conducted in Bihar. Quality of FAB has also been flagged as a major concern. To address these concerns, DA Group, in 2018, carried out a survey of all 38 districts in Bihar and mapped the FAB enterprises on an interactive Geographic Information System (GIS).

The ellipses on the map (shown above) identify potential clusters that could be developed with support from government and private stakeholders. Key highlights

TARA is also leveraging public and private support institutions to facilitate creation of Common Facility Centre (CFC) and infrastructure development for the FAB clusters. A CFC includes facilities like testing, training, design, marketing display/selling, effluent treatment, logistics, raw material bank/sales depot, etc. Similarly, infrastructure development consists of facilities like power distribution network, water, telecommunication, drainage and pollution control facilities, roads, banks, raw material storage and marketing outlets, common service facilities and technological backup services. These facilities support sustainability and growth of FAB enterprises by addressing common issues such as improvement of technology, skills and quality, access to quality raw material, market and capital. ■

Sudhir Sah

References: |