NGO

– Business Environmental Partnerships

-A Promising Approach

to Promote Cleaner Production

Dr. (Mrs.) K Vijaya Lakshmi |

Over

the past 20 years, Non Government Organisations (NGOs) have moved from the

welfare sector to the field of development. They have now taken the next big

step towards community investment with business partners. This means working

actively with private businesses and local governments to carry out activities

that benefit both. It entails addressing environmental problems, promoting waste

management and the use of clean technology and reducing pollution. Following are

the case studies (wherein Development Alternatives (DA) was the NGO partner)

that illustrate the potential of these partnerships in promoting sustainable

industrial environment management practices.

The US-AEP Program

The NGO-Business Environment Partnership was conceived in 1994 as an

alternative to the traditional antagonism of pro-environment versus pro-business

sector. The NGO- Business Programme focused on the exploration of "if and

how" NGOs and business could work together. It provides incentive grants to

Asian NGOs to promote their collaboration with private businesses and local

governments to address environmental problems and reduce pollution. The main

expectations of the grant programme were to:

n

strengthen the

capacity of the Asian NGOs to work co-operatively with industry;

n enhance awareness

about the potential for integrating the practices to improve the

work place

environment with profitable business practices; and

n encourage sharing of

strategies among NGOs.

Table I :

Avoidable Financial Losses in a Typical Nickel Plating Unit

| Type of loss |

source |

|

Quantity per annum |

Loss per annum |

|

Reason |

| Loss of nickel through drips |

Bath & rinse tanks |

|

| Nickel loss through dragout |

Bath & rinse tanks |

|

Lack of drag-out recovery system |

| Wasteful Nickel deposition on copper hangers |

Plating Bath |

|

Lack of plastic coating on copper wire hangers |

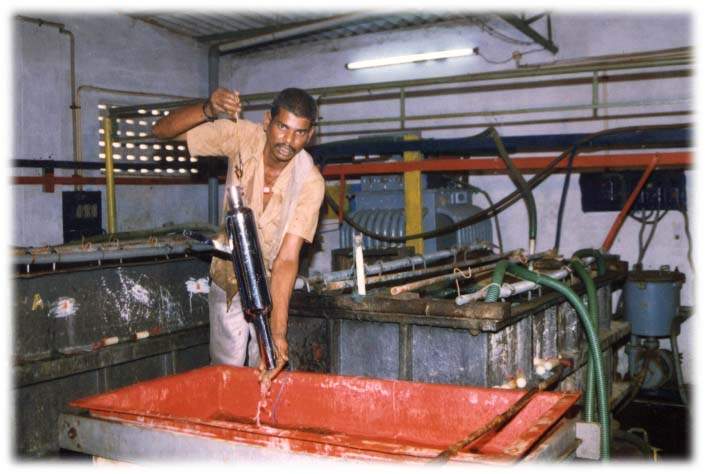

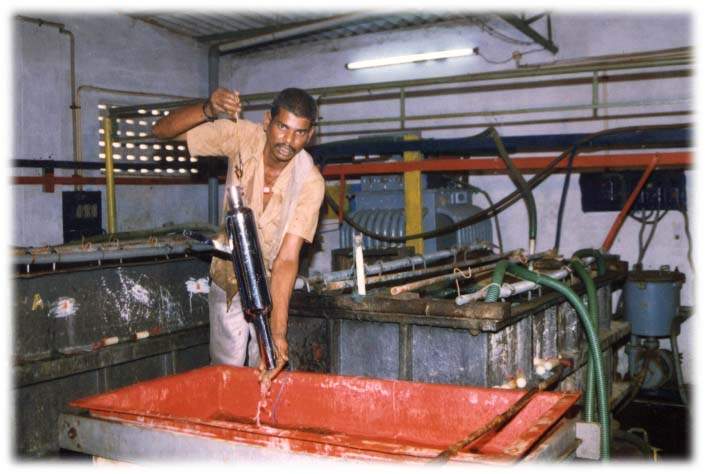

Waste Minimisation in Electroplat-ing Sector

With the support from US-AEP and The Asia Foundation, Development

Alternatives has established a partnership with Anand Parbat Industry

Association in Delhi to demonstrate cleaner production practices in selected

electroplating units to facilitate further adoption of these technologies by

the industrial units at Anand Parbat.

The approach

After a careful survey of several units, DA selected representative

units of Nickel-Chromium and Zinc-Cyanide to demonstrate the techno-economic

feasibility and environmental viability of various cleaner-production options.

Detailed unit level audits were conducted to pinpoint the lapses in production

practices that were the main cause of financial losses to the units (Table I).

Table II – Techno-economic feasibility of few selected

options in a Nickel-Chromium unit

|

|

|

|

Case I:

Nickel-Chromium Unit (Electrical parts)

Hanging Technique ; Drag-out collection Tank

Fume suppressants |

|

|

|

Rs. 1,25,000/-

annum

8000 kg of Nickel /annum |

|

Case II:

Nickel-Chromium Plating (Automobile

Parts)

Drag-out loss recovery; PVC coating of jigs & fixtures

Fume suppressant use exhaust & ventilation

Reduction of distance between bus bars and rectifiers. |

|

|

|

Case III:

Nickel-Chromium Unit

- Use of jigs &

fixtures

-Eco-cascade rinsing tank |

|

Rs. 20,000 (once in

6-8 months)

Rs. 30,000/-

(one time investment) |

|

Rs. 1,10,000 /

annum

Playback period 2-3 months

Rs. 1,70,000 / per annum +

reduced water requirement

Playback period: 2.5-3 months |

|

For each of the potential losses, prevention options were

identified and the techno-economic feasibility was worked out before

demonstrating some viable options in the selected units (Table II).

Following the best practice demonstration, DA is further disseminating the

information to the other units in Anand Parbat industrial area and also to the

units outside Delhi, such as Hyderabad and Ludhiana, with the help of

industrial associations in these cities. DA is also providing training

programmes to shop-floor workforce and lectures to urban environmental

managers.

US-AEP has selected DA-Anand Parbat partnership as one of the 9 flagship

projects out of the 51 projects that it has supported across Asia-Pacific.

Recently, all the nine flag-ship project leaders from Thailand, Philippines,

India, Bangladesh, Nepal, Indonesia, Taiwan, etc., met at Bangkok and formed

the Asia-working group to further promote such efforts through sharing,

exchange visits and joint initiatives. Several experience-sharing initiatives

have already begun in all these countries. For example, DA is promoting ‘green’

practices among the Hotel & Restaurant sector, drawing insights from the

efforts taken up by NGOs in Philippines, Thailand and Indonesia.

Green Business

Opportunities for Hotel Industry

In furtherance of the general goals

of the US-AEP Environmental Partnership, DA got the grant to collaborate with

local and regional partners to work with the hotel and restaurant sector in

India. The basic premise of this programme is to rationalise the sector’s

use of natural resources (water, energy, food etc.) and reduce its generation

of waste. DA has formed a formal partnership with the Hotel And Restaurant

Association of Northern India (HRANI).

DA has conducted environmental audits in a Five Star hotel to check the solid

waste generated from the kitchen, guest-rooms and public areas. It was found

that Hotel Industry could gain financially by proper management of solid waste

by:

n

by reducing the

quantity of waste produced

n disposing over-

packaged goods

n

encouraging suppliers

to change production processes to generate fewer unusable

by-products.

n

eliminating the usage

of hazardous material

n

reusing items in their original form for

the same or for a different purpose. Items

such as refillable bottles, cloth

towels and laundry bags, washable napkins an

rechargeable batteries, and many other products that can be

used many times.

The SDC Programme

Swiss Agency for Development and Co-operation (SDC) has

initiated an innovative multi-stakeholder partnership programme for adopting

and promoting a cleaner technology in the most unorganised Burnt Brick

Production sector in India. In search for an alternative clean technology, DA

came across the Vertical Shaft Brick Kiln (VSBK) technology from China.

An action research programme was started in 1995, financed

by SDC, co-ordinated / implemented by DA in association with Tata Energy

Research Institute (TERI) and guided by Swiss consulting organisations (SKAT

and Sorane) and by Chinese energy experts. (For details see article on Page

9).

As India is all set to progress at a rapid pace in the new millennium, the

magnitude of pollution and resource-intensiveness of various small and medium

enterprises, especially the service enterprises, may outweigh even the

contribution by large enterprises. Therefore, it is highly desirable to

nurture many more partnerships such as the ones mentioned above to promote the

voluntary initiatives for environmental management.