Background

Burnt clay bricks will continue, in the foreseeable future, to be the major walling material for construction of dwelling units, required in large numbers to meet the increasing shelter demand of the masses.

The conventional practices of firing clay bricks in Bull’s Trench kilns and rural country clamps consume huge quantities of energy in terms of coal, firewood and other fuels. They are also notorious as highly polluting establishments affecting the health of the flora (orchards and agricultural fields), fauna and human beings. This aspect has attracted considerable attention and strict action by the environmental authorities. The Central Pollution Control Board has issued a gazette notification severely restricting the polluting brick kilns. The environmentalists have also issued several court orders in this regard following public interest litigation initiatives. The brick industry has been advised to improve the traditional technology to check pollution or adopt new technologies.

One such technology is the Vertical Shaft Brick Kiln (or VSBK) technology, which was developed in China and has had a tremendous growth in that country over the last few decades. The technology is claimed to consume less energy for burning bricks and is also less polluting. It was planned to evaluate these claims under Indian conditions by setting up some pilot units, and if validated to work for large-scale dissemination.

A project was started by Development Alternatives with the support of Swiss Agency for Development Co-operation in 1994: one pilot kiln was constructed in 1996 at Datia in Madhya Pradesh, near Jhansi. The kiln worked during two brick seasons by 1997 and the initial results confirmed the energy efficiency of the technology. The various agencies associated with the project at this stage, and evolution of a long-term strategy to subsequently associate more implementing agencies as partners are described in the following paragraphs.

Beginning of a Vertical Partnership

Development Alternatives, a leading NGO with concerns for sustainable livelihoods, conceived the action research programme on sustainable production systems for construction materials including brick kilns. The Swiss Agency for Development and Co-operation supported the project, within its "Energy Efficient and Renewable Energy Sources" programme.

The Tata Energy Research Institute -a major Indian organisation in the field of energy and environment - was another significant member of the project team, contributing to the energy aspects. SKAT and Sorane, two Swiss consulting organisations, were assigned advisory and backstopping responsibilities for the project. A Chinese expert team from the Energy Research Institute of the Henan Academy of Sciences was engaged on a long-term basis for providing the technology support. The All India Brick and Tile Manufacturers Federation (AIBTMF) and its member units were involved in identifying the pressing needs and priority interventions needed by the brick industry.

Horizontal Expansion

At this juncture of the project, it was felt that to build capabilities for wider dissemination of the technology, more pilot VSBKs in India should be established in association with other organisations working in partnership with a wide geographical and sectoral spread.

It was decided to set up the second unit through a partner organisation at a location with a different agro–climatic scenario. A well defined, structured, procedure for selection of the partner was followed. Finally, it was decided to build the second kiln in the coastal area of Orissa, in association with Gram Vikas, a leading non-government organisation of the area. Thus, the VSBK technology moved to eastern India.

Gram Vikas is a grassroots rural development voluntary agency working in the state of Orissa. The main mission of Gram Vikas is integrated rural development, encompassing various components of rural life such as habitat, health and hygiene, drinking water, environmental sanitation, basic education, natural resource management, livelihood generation and community action for development. Gram Vikas showed interested in the VSBK technology because:

- It was embarking on a rather large housing programme and felt that the VSBK technology could be used to advantage to produce bricks economically and to locate small scale decentralised units nearer to the place of use.

- Gram Vikas works in quite a few villages, where the people are landless and are brick moulders. These people explored the possibility of using the VSBK technology to set up kilns that they could own collectively and also graduate from being merely sellers of labour to owners of capital, with the help of Gram Vikas.

With these different conceptions, the two organisations signed a Memorandum of Understanding on February 25, 1997, (see DA Newsletter April 1997 Vol. 7 No. 4 for details) which set the ball rolling for speedy implementation.

Thus, the second kiln was built in Kankia, near Mohuda village and Berhampur town in Ganjam District of Orissa in partnership with Gram Vikas.

Third Partner : Comtrust

The third kiln was set up at Palghat, Kerala in partnership with Comtrust, headquartered at Calicut with a long history of more than 150 years in production of high quality clay products.

Comtrust, or Commonwealth Trust (India) Limited, is a charitable corporate organisation dealing with other agencies in the areas of clay products, textiles, medical care etc. In the areas of heavy clay products, it has more than 150 years of experience – its predecessor Basel Mission Tile Works started the mechanised production of clay tiles at Mangalore. (Hence, all such clay tiles are popularly known as "Mangalore tiles’). Their tile factory at Olavakkod, Palghat had an extensive capacity for the storage, preparation, extrusion and firing of clay. Comtrust recognised that the economic viability of tile production was eroding gradually due to higher input costs and stiff competition from alternative technologies. It wanted to diversify into other areas of clay production with a confirmed demand. Thus, it was drawn to the VSBK technology due to its claim of better energy efficiency and lower emissions.

Discussions were initiated between the Project Team (comprising SDC, Sorane, SKAT and DA and TERI) and Comtrust towards the end of 1997.

SKAT and DA experts visited Calicut and Palghat to finalize the respective roles of the project team and Comtrust. Finally, a four-sided Memorandum of Agreement was signed amongst SDC, DA, TERI and Comtrust in April 1998.

Thus, VSBK – 3 was set up in April – May 1998 at Palghat with two shafts, one of 1m X 1.75m and the other of 1m X 2m size. Subsequently, two more shafts (of 1m X 1.75m size) have been constructed in line with the earlier shafts, with a view to absorb the redundant workforce, increase production and improve economic viability.

Fourth Partner : MITCON - DAMLE

The fourth kiln was constructed at Pune, Maharashtra in partnership with MITCON-DAMLE, a professional combine of MITCON, a consultancy organisation engaged in entrepreneur development based on energy efficient and eco-friendly technologies and Shri Anand Damle, a practising technology expert with a long experience in bricks and heavy clay products.

MITCON is an entrepreneur development consultancy organisation with significant thrust in promoting technologies promising cleaner alternatives. It has a reputation for supporting and building capacities among various levels of entrepreneurs.

Damle Clay Structurals Ltd, headed by Mr Anand Damle, provides turnkey consultancy in the field of brick-making ranging from soil selection and preparation, mechanised moulding, firing and material handling.

The project team discussed and agreed to the terms of association with the combine of the two organisations, who wanted to set up a VSBK through a partnership of entrepreneurs -Thambe and Bhagwath - namely Modern Brick Industries, who have had long years of experience in construction and real estate business.

DA provided the technical support for design, construction and initial firing of VSBK in 1998 and 1999.

(Subsequently, MITCON and DAMLE have been separately associated with the project in their respective capacities).

Salient features of the partnership

During the progress of the project, DA has participated in the team of partners in a spirit of primus inter pares (first among equals) by leading and co-ordinating all the activities. This has built a sense of camaraderie and bonhomie amongst the partners in their working, with benefits to all in a win-win situation. Some of the major activities and their benefits are enumerated below.

1. Experience Exchange

Frequent meetings of the partners are held, with the participation of backstoppers, technical experts and stakeholders. The experiences of the partners in areas of production, technology, capacity building, economics and quality are freely exchanged, with immense benefits to all. Two formal meetings of the Joint Plant Committee have been held at Palghat and Gram Vikas. The relative strengths available with individual partners in the areas of clay technology, design, construction, operation, social aspects, energy and environment are shared for common good.

2. Capacity Building

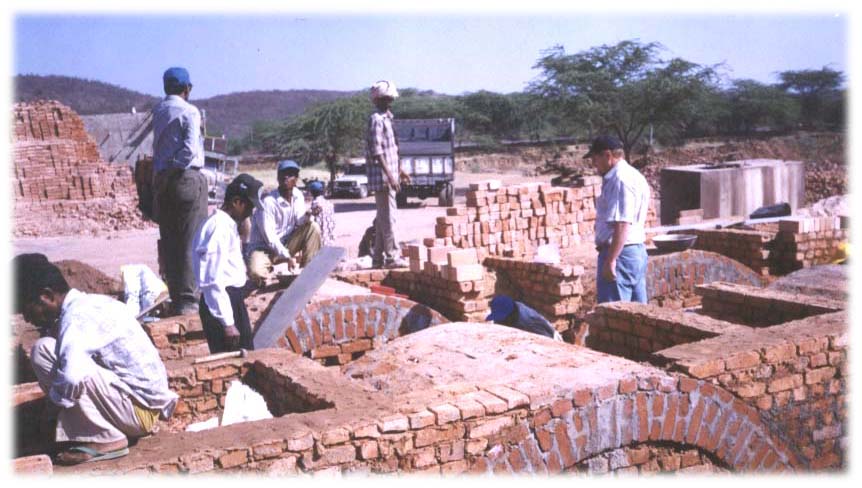

Design: Before construction of any new kiln, Design Workshops are held where design parameters are evolved in a participatory mode. Then, actual hands-on exercise of designing takes place among representatives from all partners to enable development of requisite design skills.

Construction : Supervisors and masons (from all partners) are encouraged to participate in the construction of new kilns to enhance their competence in this area. Structured VSBK Mason Training Workshops are also held. DA engineers and masons also work with their counterparts during the construction of new kilns.

Firing: Supervisors, Fire-masters and Firemen are encouraged to participate in the firing of kilns at the premises of different partners. The support of DA and Chinese experts is also provided during the initial firing of kilns at the premises of partners.

3. Technology and Quality

There is a significant stress on the continuous improvement of practices to ensure higher levels of quality brick-production. The technical aspects are discussed in Technical Group Meets, where brainstorming sessions are held to identify the technical factors contributing to better production. Protocols for Research and Development actions to enable better understanding of phenomena are evolved. Formal training courses on clays and firing are held with national and international resource persons. Two multi partner task forces have been set up to address the identified (immediate) needs :

– the VSBK Drying Group

– VSBK Firing Document Task Force

4. Economics

The economics of operation of the VSBK technology are discussed during the Joint Partner Meetings. Actions to improve economic performance and bankability of the technology are identified for implementation. Assistance of outside experts in business and commercial aspects is arranged to support the partners to develop their own Business Plans.

5. Documentation

Documents in the print and visual media are produced and made available to the partners. This helps in creating awareness about the technology and providing preliminary information to the target groups.

A Quarterly Bulletin, with inputs from all the partners, is regularly produced to

keep all the project team members informed about the latest status and achievements. The salient features of the operating kilns at the moment are given in the table at the bottom of the page.

Salient Features of different Vertical Shaft Brick

Klins

| VSVK 1 | VSVK 2 | VSVK 3 | VSVK 4 | VSVK 5 | |

| Location | Datia, MP | Kanika,Orissa | Palghat,Kerla | Pune, Maharashtra | Gwalior, MP |

| Organization | DA handed over toAslam | Gram Vikas | Comtrust | MITCON-DAMLE | Yade Brick Industries |

| No of Shafts | 2 | 2 | 2+2 | 2 | 2+2 |

| Shaft size | 1 x 1 m 1 x 1.5 m |

2 x 1.75 m | 3 x 1.75 m 1 x 2 m |

1 x 2 m 1.5 x 2 m |

4 x 2 m |

| Production capacity |

~5000per.day | ~ 7000 per.day | ~14500per.day | ~ 9500 per.day | ~ 16000 per.day |

The awareness on the VSBK technology has spread in all the four regions of the country. The brickmakers are showing a keen interest in the technology. There is a tremendous response to the technology in terms of the huge number of requests from entrepreneurs to set up VSBKs in their premises.

The project would like to increase the numbers in a planned and structured fashion. Planning is afoot to route the project through pre-dissemination and subsequent large-scale dissemination phases.

Conclusion

The VSBK project partner team in India is spread over all the regions of the country – DA in the north, Gram Vikas in the east, Comtrust in the south and MITCON and Damle in the west.

The technology transfer has been facilitated with initial inputs from the Henan Academy of Sciences, China. Project implementation has been designed with the technical support of international consultants Sorane and SKAT. The Indian technology promoters have been responsible for the pioneering efforts to indigenize the technology, with the co-ordination being provided by Development Alternatives.

The industrial partners have been leading the upscaling of the technology and establishing economic viability under a variety of regional conditions. The task force has engaged partner organisations for successful demonstration of the technology in different regions having varying geo-climatic conditions, different soil and fuel combinations and varying market conditions.

At the inception stage itself, industrial partners producing burnt clay products have been integrated into the programme for defining high-quality brick production standards. A team of local and international consultants is leading the initiative to improve resource-productivity and to widen the applicability of the VSBK technology to a wider variety of soils. Energy and environmental monitoring teams at all kiln sites have been engaged to ensure the reliability of the VSBK technology in terms of high environmental performance. Particular emphasis is being laid on achieving operational health and safety conditions, which are largely ignored at most of the kiln sites even in the organised sector. A pool of practitioners is being trained in all the aspects of construction, operation and maintenance.

This multiple stakeholder initiative plans to engage national level regulatory bodies like the Central Pollution Control Board to validate the environmental performance of the VSBK technology. The Building Materials Technology Promotion Council (Government of India) will validate the technical claims and economic viability of brick production through the VSBK technology. These are visualised as crucial steps for the large-scale dissemination and for meeting the long-term needs of brick kiln owners. The overall objective of the task force is to guide the evolution of the VSBK technology in India, leading to the formulation of a strategy for large-scale dissemination.