|

Japan’s Sound Material Cycle Society

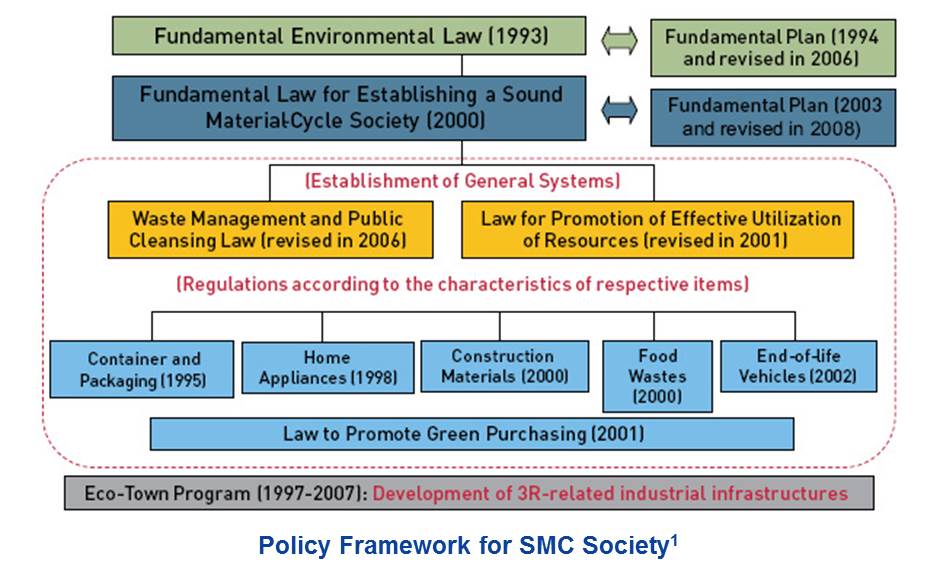

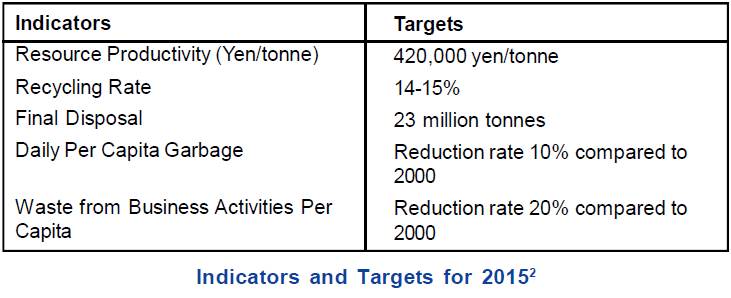

G lobally, economic growth has been achieved at the expense of the environment. Countries are grappling with issues of resource crunch and waste generation. This trend is also reflected in Asia including Japan. To address these issues, policymakers are targeting the transition towards a Junkan-gata-shakai or Sound Material-Cycle (SMC) Society. A SMC society is characterised by minimal consumption of natural resources, prevention of waste generation, recycling of products and appropriate final disposal of waste. In order to establish a SMC society, Japan has been involved in developing and implementing waste minimisation and recycling policies since 1990. Some of these laws include Law for Promotion of Sorted Collection and Recycling of Containers and Packaging (1995), Law for the Recycling of Construction Materials (2000), Law for the Recycling of End-of-Life Vehicles (2002) etc.The year 2000 stands out as a landm Monitoring Progress of Resource Efficiency Policies Material flow accounting has been central to monitoring the progress of implementation of the fundamental plan. Indicators and policy targets have been formulated for 2015. Two types of quantitative indicators were developed: • Material Flow Indicators: They aim at reducing per unit resource inputs, reducing final disposal of wastes and promoting cyclical use of materials.

Targets have also been specified for recycling of construction wastes like concrete blocks, wood and sludge etc. Looking at the progress against these targets, resource productivity amounted to 374,000 yen/tonne, cyclical use rate improved to 15.3%, and final disposal amount declined to 19 million tonnes. The increase of resource productivity excluding earth and rocks has been steady with a 10% increase from 2000 to 2010. However, it is still a long way to meet the target. Funding for Resource Efficiency The Development Bank of Japan (DBJ) has been actively involved in promoting the SMC society by funding progressive companies striving to achieve resource efficiency. Under the scheme of Promotion of Environmentally Conscious Management (2004), DBJ developed the world’s first system of financing based on environmentally responsible ratings. Preferential interest rates for direct loan repayment are provided to the companies based on their rating. These ratings are decided after a qualitative and quantitative assessment of a company’s environmental performance in three areas, namely: • efforts in reducing greenhouse gas emissions and waste generation • overall management, assessing compliance and information disclosure • evaluation of the entire supply chain from procurement and manufacturing to supply and sales. 120 questions were developed based on the exchange of information with the United Nations Environment Programme Finance Initiative and Japan’s Ministry of the Environment to aid this assessment. Under this scheme, finance totalling to approximately 85 billion yen was extended to 64 companies in 2005 alone. 60% of the companies were majorly from the manufacturing sector. More than 100 ratings have been conducted since the introduction of this scheme 3. Some of the leading recipients related to the construction sector include Asahi Industries Co. Ltd., Sumitomo Osaka Cement Co. Ltd, Takenaka Corporation etc4.Japan has been involved in promoting such initiatives in other countries as well. It supported the formulation of plans and strategies for promoting the 3Rs in countries like Indonesia and Vietnam and promoted dialogues on these issues with China and Korea. It also proposed the inauguration of the ‘Regional 3R Forum in Asia’ to provide a platform for inter-regional cooperation for promoting the 3Rs through implementation of pilot projects and the promotion of research cooperation 5. Japan’s efforts in promoting resource efficiency have been noteworthy. Such efforts should be replicated by other countries as well. qDandapani Varsha Endnotes 1 Hotta, Yasuhiko (2011). Is Resource Efficiency a Solution for Sustainability Challenges?, S.A.P.I.EN.S [Online], Accessed on 29 October 2015. URL : http://sapiens.revues.org/1161 2 Government of Japan (2013). Fundamental Plan for Establishing a Sound Material-Cycle Society. 3 Bahn-Walkowiak et al. (2008). Resource Efficiency: Japan and Europe at the Forefront. Synopsis of the Project and Conference Results and Outlook on a Japanese-German Cooperation 4 http://www.dbj.jp/en/ 5 Ministry of Environment (2010). Establishing a sound material-cycle society Milestone toward a sound material-cycle society through changes in business and life styles. Government of Japan |

ark year when the

focus of the Japanese government shifted from waste management to

resource utilisation and eco-efficiency. The Fundamental Law for

Establishing a Sound Material Cycle Society was formulated in 2000.

It is based on the 3R principles of reduce, reuse and recycle. The

Fundamental Plan for Establishing a Sound Material-Cycle Society was

launched in 2003 and revised in 2008 and 2013. It aims to reduce the

total material input and resource use, minimise waste generation and

promote reuse and recycling of products and resources. It establishes

numerical targets and defines the expected roles of several stakeholders

including government, civil society, businesses and citizens to achieve

this transition to a SMC society.

ark year when the

focus of the Japanese government shifted from waste management to

resource utilisation and eco-efficiency. The Fundamental Law for

Establishing a Sound Material Cycle Society was formulated in 2000.

It is based on the 3R principles of reduce, reuse and recycle. The

Fundamental Plan for Establishing a Sound Material-Cycle Society was

launched in 2003 and revised in 2008 and 2013. It aims to reduce the

total material input and resource use, minimise waste generation and

promote reuse and recycling of products and resources. It establishes

numerical targets and defines the expected roles of several stakeholders

including government, civil society, businesses and citizens to achieve

this transition to a SMC society.  • Targets Concerning Waste Management Effort Indices:

They were formulated with the intention of tracking progress of efforts

undertaken by various entities and different laws towards a SMC Society.

• Targets Concerning Waste Management Effort Indices:

They were formulated with the intention of tracking progress of efforts

undertaken by various entities and different laws towards a SMC Society.