Building Inclusive Economy through Waste Recycling

Sustainability of any sector can be realised only through mutli-dimensional approaches. Realising the need for resource efficiency in India, many industry initiatives have addressed this aspect. Foundry sector is a sector in which the small-scale foundries contribute to huge amount of waste. The decentralised waste generation system comes along with high waste management cost due to geographic distribution. Managing such waste in a centralised process would be a even higher cost consuming process. Development Alternatives being one of the pioneers in providing sustainable technology solutions, has identified strategies to utilise such foundry waste with productive environmental and economic benefits. The strategy also focuses on creating local economy in the cluster such that the value creation is a catalyst for adoption. Through many consultations with foundry industries and other MSME industries, it has been found that the construction sector can make use of the slag i.e. the waste from the foundry units as replacement of its demand of the aggregates in the non-structural building materials. The non-structural building sector consumes high amount of the natural aggregates to obtain building products.

Foundry slag obtained by the coupla induction process  is waste from the ferrous industries which is usually dumped in the landfill. This residue has its own characteristic which causes undesirable effects on the environment. The waste stream has currently no value in the sector. Managing such a waste stream becomes a cost consuming process for the foundry industries. On the other hand, the construction industries experience high demand for quality building resources such as natural aggregates, sand and cement.

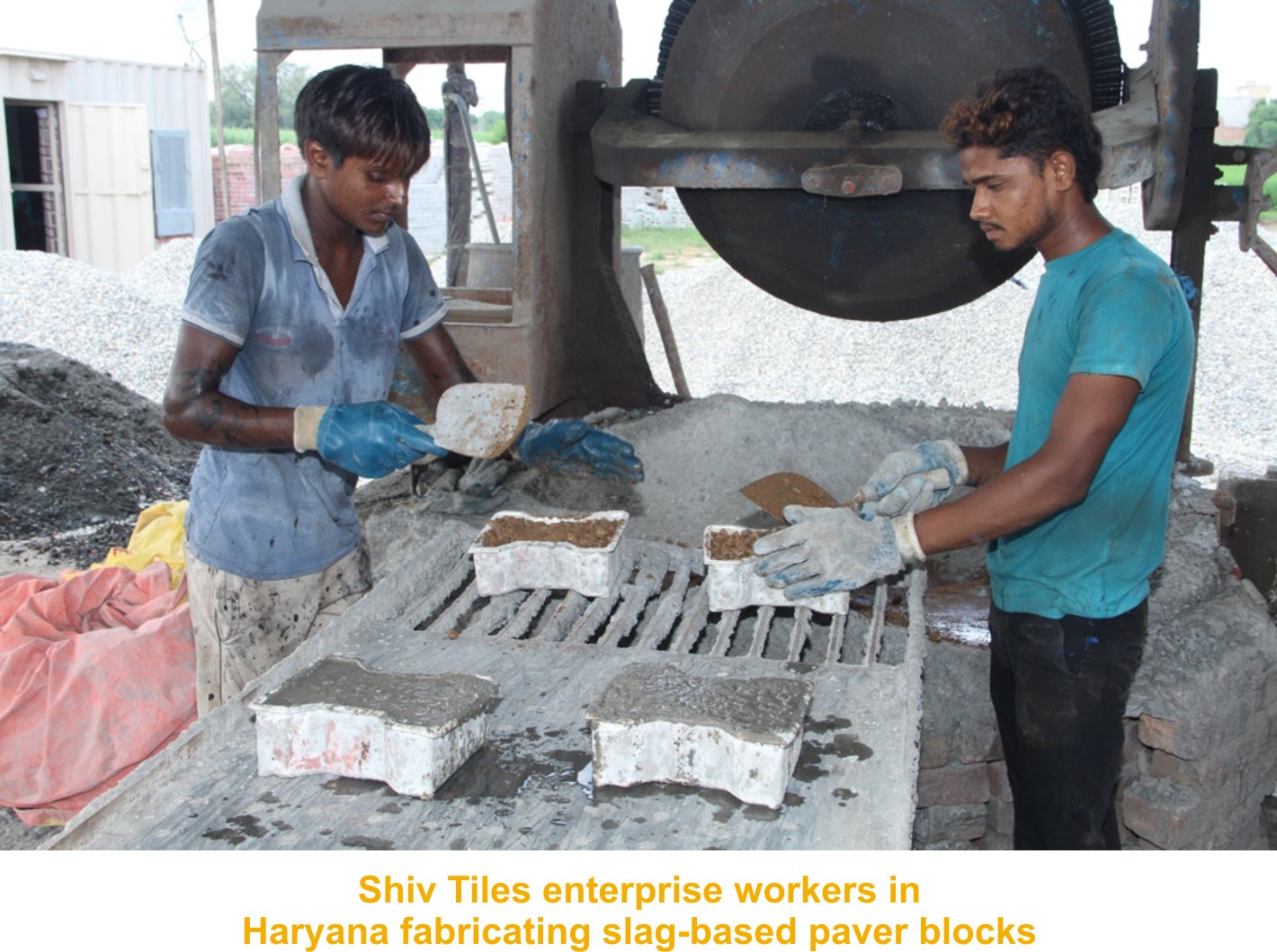

The adoptive innovative solution of utilising foundry slag as the natural aggregate material in paver blocks is experimentally developed and validated by Development Alternatives through physical and chemical characterisation. The technology solution has changed the scenario of slag management to a profitable business solution. The dissemination initiatives have been carried out by Development Alternatives and Foundation for MSME clusters in the foundry clusters through sensitisation workshops, consultation meetings, technical intervention, pilot demonstration and technical assistance on troubleshooting.

The technology solution enables paver manufacturers to produce quality paver blocks using crushed slag with a conventional paver fabrication process. The observed result on the compressive strength and water absorption exceeds the required Indian construction BIS standards.

Each enterprise can produce its average production of 2500 pavers a day using 6 tonnes of the crushed slag. Through utilising the crushed slag in the paver manufacturing process, the foundry cluster creates economic value for the slag. In addition to that slag is one of the resources accessible in the near region of the paver units so the cost of the production of the paver reduces to the extent in the range of Rs.1.50- 0.40 per paver, which is the 14.5% to 4.5% of the total production cost per paver. The reduction of the production cost is varied with respect to the geographic location of the slag availability and cost of the natural aggregates in the region. By using slag as the replacement of the natural aggregates, the technology benefits both foundry and paver manufacturers to utlise the foundry slag as a primary resource in the building materials fabrication.

■

is waste from the ferrous industries which is usually dumped in the landfill. This residue has its own characteristic which causes undesirable effects on the environment. The waste stream has currently no value in the sector. Managing such a waste stream becomes a cost consuming process for the foundry industries. On the other hand, the construction industries experience high demand for quality building resources such as natural aggregates, sand and cement.

The adoptive innovative solution of utilising foundry slag as the natural aggregate material in paver blocks is experimentally developed and validated by Development Alternatives through physical and chemical characterisation. The technology solution has changed the scenario of slag management to a profitable business solution. The dissemination initiatives have been carried out by Development Alternatives and Foundation for MSME clusters in the foundry clusters through sensitisation workshops, consultation meetings, technical intervention, pilot demonstration and technical assistance on troubleshooting.

The technology solution enables paver manufacturers to produce quality paver blocks using crushed slag with a conventional paver fabrication process. The observed result on the compressive strength and water absorption exceeds the required Indian construction BIS standards.

Each enterprise can produce its average production of 2500 pavers a day using 6 tonnes of the crushed slag. Through utilising the crushed slag in the paver manufacturing process, the foundry cluster creates economic value for the slag. In addition to that slag is one of the resources accessible in the near region of the paver units so the cost of the production of the paver reduces to the extent in the range of Rs.1.50- 0.40 per paver, which is the 14.5% to 4.5% of the total production cost per paver. The reduction of the production cost is varied with respect to the geographic location of the slag availability and cost of the natural aggregates in the region. By using slag as the replacement of the natural aggregates, the technology benefits both foundry and paver manufacturers to utlise the foundry slag as a primary resource in the building materials fabrication.

■

Atheeque Ahmed

aahmed@devalt.org