Tracking SDG Implementation: LC3

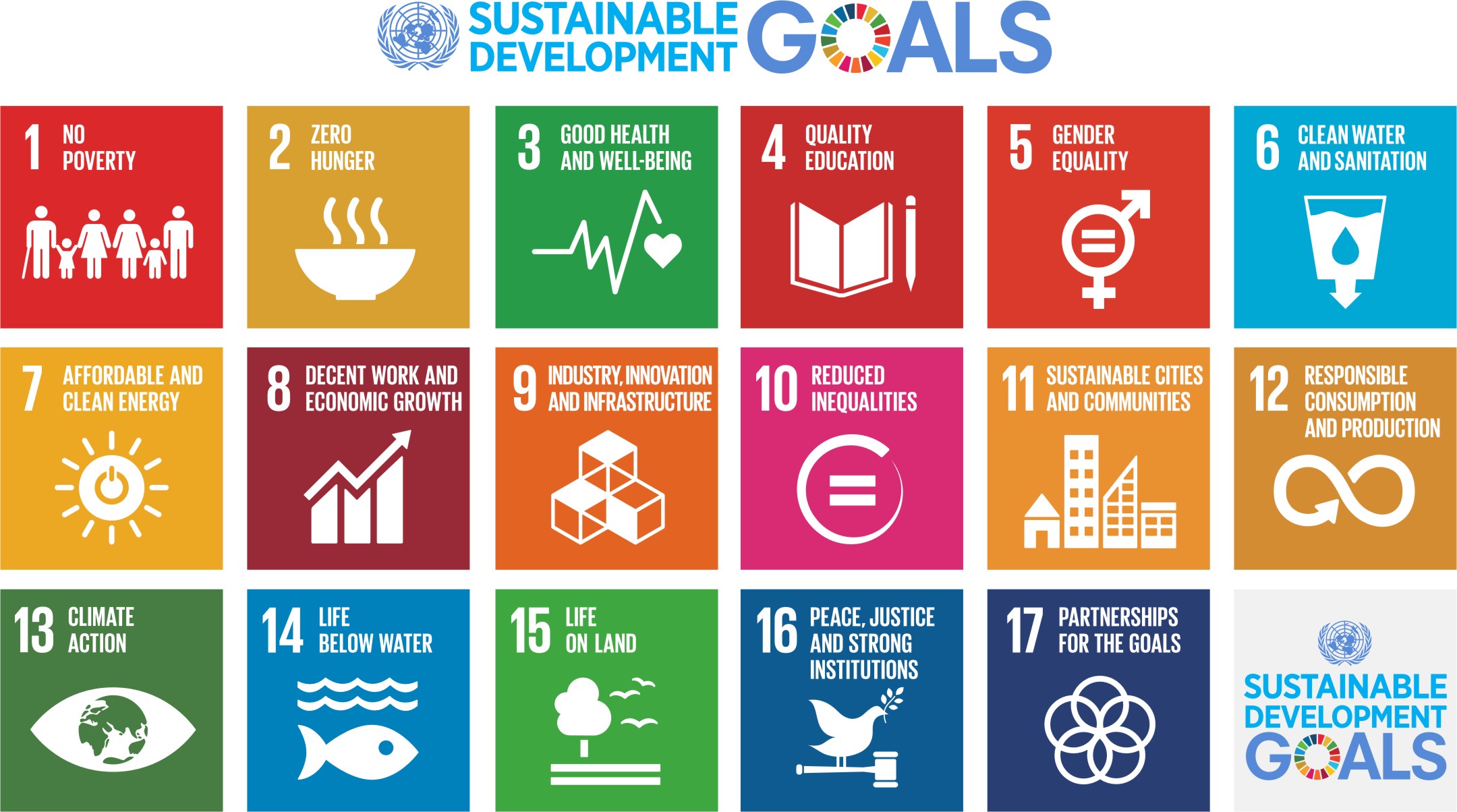

Sustainable Development Goals (SDGs) were adopted by the UN General Assembly in September 2015. These are the blueprints to achieve a better and more sustainable future for all. SDGs address the global challenges we face, including those related to poverty, inequality, climate change, environmental degradation, prosperity, peace and justice. The 17 sustainable development goals (SDGs) to transform the world are as given in the figure below.

Implementation of SDGs is closely related to governance, which in turn, has many different aspects such as decision making, monitoring and evaluation, accountability, transparency, etc. Governance also occurs at multiple levels including global, regional, national and subnational. Mainstreaming sustainability issues into other policy areas is one key issue. Lack of data on many targets and indicators is also a major challenge to implementation and an obstacle to effective governance. Many different stakeholders are expected to be involved in implementation. The SDGs were created by national governments, which bear the final responsibility. However, major efforts from business and civil society will be indispensable and cities and other subnational governments will play key roles. The UN, multilateral development banks and other international organisations will assist, not only at the global level, but also at the regional, national and local levels.

LC3 Technology

LC3 belongs to a family of composite cements containing clinker, calcined clay and limestone. LC3 technology promises a sustainable growth of economies around the world by reducing CO2 emissions by more than 30% compared to plain Portland cement at lower production costs. LC3 works on the synergy between clinker, calcined clay and limestone phases. Calcined clay reacts with hydration products of clinker and limestone reacts with calcined clay, giving phases that make the microstructure denser. Calcined clays have been long used as pozzolanic materials in cements and limestone is a well-established semi-reactive filler in cements. In LC3, the added synergy from the reaction of calcined clays with limestone producing carbo-aluminate phases improves the strength and durability of the cement. Due to the lower clinker content, LC3 technology has several advantages over ordinary Portland cement (OPC) and Portland pozzolanic cement (PPC).

Salient features of the LC3 technology are:

• Improved resource efficiency

• Lower CO2 emission per tonne of cement produced

• Reduced production cost without compromising the performance of the cement

• Easy processing and supported by existing production facilities hence low capital investment costs

• Almost double cement output per tonne of clinker

• Enhanced durability of the building materials and concrete produced using LC³

Linkages with SDGs

Out of these 17 goals, implementation of LC3 directly addresses five goals which are depicted below.

SDG 9: Industry, innovation and infrastructure

Manufacturing is an important driver of economic development and employment. Technological progress is the foundation of efforts to achieve environmental objectives such as increased resource and energy-efficiency. LC3 is a new generation cement and its unique features are attracting industrialists leading to economic growth and new employment in cement and infrastructure sectors.

SDG 11: Sustainable cities and communities

With the number of people living in cities projected to rise to 5 billion people by 2030, it is important that efficient urban planning and management practices are in place to deal with the challenges brought by urbanisation. Common urban challenges include congestion, shortage of adequate housing, declining infrastructure and rising air pollution within cities. LC3 is a low clinker factor cement with reduced CO2 emission which is as low as 25-30% compared to market cement.

SDG12: Responsible production and consumption

Sustainable production and consumption is about promoting resource and energy efficiency, sustainable infrastructure and providing access to basic services, green and decent jobs and a better quality of life for all. Since sustainable production and consumption aims at ‘doing more and better with less,’ net welfare gains from economic activities can increase by reducing resource use, degradation and pollution along the whole life cycle of products. LC3 improves the resource efficiency of limestone and clay mines through efficient utilisation of lower grade raw materials.

SDG13: Climate action

Weather patterns are changing, sea levels are rising and greenhouse gas emissions are now at their highest levels in history. Climate change is now affecting every country on every continent. It is disrupting national economies and affecting lives, costing communities and countries dearly. The poorest and most vulnerable people are being affected the most. In such a situation, LC3 promises affordable and saleable solutions to enable the countries to leapfrog to cleaner and more resilient economies.

SDG17: Partnerships for the goals

A successful sustainable development agenda requires partnerships between governments, private sector and civil society. These inclusive partnerships built upon principles and values, a shared vision and shared goals that place people and the planet at the center, are needed at the global, regional, national and local level.

LC3 technology has been developed and disseminated by joint collaborations and participations among academia, industries, research organisations, bilateral and multilateral agencies with national and international repute.

Cement Sustainability Initiative (CSI)

• Improved resource efficiency

• Lower CO2 emission per tonne of cement produced

• Reduced production cost without compromising the performance of the cement

• Easy processing and supported by existing production facilities hence low capital investment costs

• Almost double cement output per tonne of clinker

• Enhanced durability of the building materials and concrete produced using LC³

Linkages with SDGs

Out of these 17 goals, implementation of LC3 directly addresses five goals which are depicted below.

SDG 9: Industry, innovation and infrastructure

Manufacturing is an important driver of economic development and employment. Technological progress is the foundation of efforts to achieve environmental objectives such as increased resource and energy-efficiency. LC3 is a new generation cement and its unique features are attracting industrialists leading to economic growth and new employment in cement and infrastructure sectors.

SDG 11: Sustainable cities and communities

With the number of people living in cities projected to rise to 5 billion people by 2030, it is important that efficient urban planning and management practices are in place to deal with the challenges brought by urbanisation. Common urban challenges include congestion, shortage of adequate housing, declining infrastructure and rising air pollution within cities. LC3 is a low clinker factor cement with reduced CO2 emission which is as low as 25-30% compared to market cement.

SDG12: Responsible production and consumption

Sustainable production and consumption is about promoting resource and energy efficiency, sustainable infrastructure and providing access to basic services, green and decent jobs and a better quality of life for all. Since sustainable production and consumption aims at ‘doing more and better with less,’ net welfare gains from economic activities can increase by reducing resource use, degradation and pollution along the whole life cycle of products. LC3 improves the resource efficiency of limestone and clay mines through efficient utilisation of lower grade raw materials.

SDG13: Climate action

Weather patterns are changing, sea levels are rising and greenhouse gas emissions are now at their highest levels in history. Climate change is now affecting every country on every continent. It is disrupting national economies and affecting lives, costing communities and countries dearly. The poorest and most vulnerable people are being affected the most. In such a situation, LC3 promises affordable and saleable solutions to enable the countries to leapfrog to cleaner and more resilient economies.

SDG17: Partnerships for the goals

A successful sustainable development agenda requires partnerships between governments, private sector and civil society. These inclusive partnerships built upon principles and values, a shared vision and shared goals that place people and the planet at the center, are needed at the global, regional, national and local level.

LC3 technology has been developed and disseminated by joint collaborations and participations among academia, industries, research organisations, bilateral and multilateral agencies with national and international repute.

Cement Sustainability Initiative (CSI)

The Cement Sustainability Initiative (CSI) is a global effort by 24 major cement producers with operations in more than 100 countries. CSI members believe there is a strong business case for the pursuit of sustainable development. Collectively these companies account for around 30% of the world’s cement production and range in size from very large multinationals to smaller local producers. CSI claims that it remains one of the largest global sustainability programmes undertaken by a single industry sector. Over the past, CSI has focused on understanding, managing and minimising the impacts of cement production and use by addressing a range of issues, including: climate change, fuel use, employee health and safety, airborne emissions, concrete recycling and quarry management. Purpose of CSI • Explore what sustainable development means for the cement industry • Identify actions and facilitate steps cement companies can take, individually and as a group, to accelerate progress toward sustainable development • Provide a framework for other cement companies to become involved • Create the content and context for further stakeholder engagement With the goal to strengthen the communication and exchange of cement kiln co-processing technology, promote the transformation and upgrading of the industry and contribute to the construction of ecological civilisation and environmental protection; China Resources Cement Holdings hosted the CSI in China at its Tianyang operation site on 20 September 2018. According to a report developed by the IEA and the CSI, combination of technology and policy solutions could provide a pathway to reducing direct carbon dioxide emissions from the cement industry by 24% below current levels by 2050.

Palas Kumar Haldar

pkhaldar@devalt.org