|

VSBK Sucess Story

Siyaram Rathore, Champa, Chattisgarh

He

bought a small manual stone crushing unit after selling his newly wed

wife’s jewellery. Thus started an enviable history of success. After

modernization of the stone crusher, he invested into a movable chimney

which was also successful. Investing in the fuel saving VSBK technology

consolidated his position in the market due to better quality and

increased margins. He has future plans of expanding his two shaft VSBK

unit into a four shaft one to produce approximately 40 lakhs of fired

bricks in a single season. This is a live example of the maxim:

“Failures are the pillars of success.”

Siyaram Rathore has benefited immensely from his investment in the Vertical Shaft Brick Kiln (VSBK) during the first year of brick production itself. His plant at Champa in Chattisgarh district of Madhya Pradesh, which started trial production in March 2004 and full-fledged production from November 2004, is a working example of technological excellence. Plant at a glance Mr. Rathore, owner of the plant is highly excited by the coal savings of the plant. During the past brick season, his plant’s average coal consumption was only one tonne per lakh of fired bricks. His traditional Movable Chimney BTK unit has been constantly consuming around 18 tons per lakh of fired bricks. His annual savings this year were to the tune of 300 tonnes of coal for a production of 18 lakh bricks. His co-operation, hard work, dedication and above all complete faith in VSBK technology and the implementation team has resulted in a wonderful cost saving solution. To reduce external fuel consumption; sponge iron waste, in the form of dust was added with the soil during the raw brick preparation. It was supplied free of charge to him from a nearby Sponge Iron Industry. While the coal available from the market is now touching Rs. 2400 per tonne, the saving is huge with no compromise on quality and reduced breakage. In my life, I have always been inspired to do things in a different manner, be it a stone crusher or bricks. My stone crusher unit was the first one in Chattisgarh to employ pollution control measures. VSBK technology gives me freedom from environment hassles and has improved my profitability and quality as compared to that of my movable chimney. VSBK also gives me the freedom to employ local manpower rather than depending upon other areas.

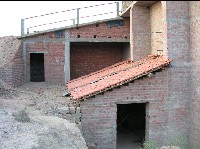

Unique feature The most outstanding feature in this kiln is the construction of the superstructure at a lower elevation (see the picture in the right corner). This saved the cost of RCC ramp for transportation of green bricks since it was made from soil filling. The space between the filling and the cooling chamber has been turned into a rest room for workers. It is the Mecca of VSBK since entrepreneurs continuously throng the site to observe the amazing low coal consumption unheard in terms of brick-firing in the whole world.

Sanjay Sharma, Kota, Rajasthan Born on 29th January, 1971 into a family of four brothers, Shri Sharma was the youngest child having a flair for independent business from his childhood days. Armed with a diploma in mechanical engineering, he started his career in 1994 at a sandstone mine as a plant engineer. After six years of service, he undertook marketing of fly ash bricks for two years. During this stint, he gained enough experience in bricks and sold around 50 lakhs of fly ash bricks. After a short stint year in marketing red bricks, he set up his own brick unit. During the period 2003-2005, he produced around 15 lakh bricks per year from small intermittent clamps.

Plant

at a glance

The first two-shaft VSBK unit in Rajasthan was constructed and commissioned in January 2005. The plant consisted of two shafts of size 1850 mm x 1070 mm, with the capacity to produce approximately 10,000 to 12,000 bricks per day. Due to the high strength of green bricks, the shaft has been designed to accommodate 12 batches. Shaft size has been designed to accommodate two brick sizes, both 8.5" x 4" x 4" and 9" x 4" x 3". The unique feature of this VSBK unit is the construction of a winch system to lift green bricks to the loading platform. It has a capacity to lift 250 bricks at a time. A metal staircase has also been constructed for people to move to the loading platform.

My intention of going

for VSBK technology was to do the brick business in a different way.

VSBK technology provides me an opportunity to change the system of brick

making in Rajasthan while setting benchmark quality standards amongst

brick producers and consumers in a profitable manner.

Throughout the season, the plant has been operating at approximately one tonne per lakh of fired bricks. Breakage of the VSBK bricks is minimal to almost nil. This has been possible due to the proper selection of soil and a judicious mix of internal fuel. To gain better strength, two types of soil are being mixed - grey coloured non-plastic and yellow coloured non-plastic. Plastic soil is being transported from his own land near a river bank. To further reduce the plasticity, fly ash obtained from a thermal power plant is mixed as per Government of India norms. Around 6% to 8% internal fuel is used (by weight) in the form of a waste from a nearby textile industry. It is a plastic material in nature, containing an oily substance. The calorific value of the waste is around 2400 KCal / Kg. All the materials are mixed dry and aged in water for at least two days. Before moulding, it is properly mixed manually. Due to the high costs of fine sand, fly ash is used as a releasing agent for demoulding bricks. The fired product is dark red in colour, hitherto unheard of in Kota. In and around Kota, bricks are mostly made in open clamps; and their colour is always a yellowish-red. Thus, Shri Sharma is able to fetch a premium of Rs.1600 per thousand for his bricks, which is almost double the rate of clamp-made bricks. The unique marketing features of his bricks are their dark red colour, proper size, good finish and a metallic ring. .q

|