|

Towards Green Lifestyle Introduction In the past few decades, there

have been tremendous efforts put in by the Central and State Governments

of our country to address the issue of rural housing shortage through

various housing schemes like Indira Awas Yojana (IAY), Mukhya Mantri

Gram Awas Yojana (MAY), Indiramma Housing Scheme, etc., for below

poverty line (BPL) families. Though addressing the rural housing

shortage has been a high priority area in the five year plans, the

output of these schemes has not been satisfactory in terms of quality,

numbers, user friendliness, environmental friendliness and cost

effectiveness. As a result, there has been tremendous wastage of

Government funds. Both national as well as local NGOs have put in

immense efforts to promote innovative, eco-friendly and low-cost housing

models in rural areas. It is an ongoing struggle to scale up these

models in an economically viable manner due to lack of awareness about

eco-friendly technologies among the rural population, shortage of

sufficient number of green building material enterprises and its supply

chain and lack of trained masons in eco-friendly construction

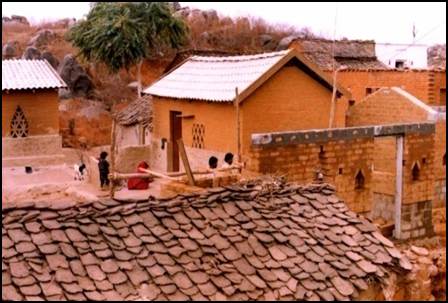

technologies. Apart from the rural houses constructed through various Government housing schemes, a large number of houses are also constructed in rural areas by the above poverty line (APL) families with their own monetary savings. Most of these houses are constructed in an incremental manner as per the savings made in a particular time period. These sections of the rural population are concerned about constructing a good quality house (aesthetically and structurally) in the least possible cost but are not always aware of the available eco-friendly construction technologies which can satisfy their needs in a cost-effective manner. They end up spending a huge amount of money, especially in Reinforced Cement Concrete (RCC) slabs and other conventional building construction technologies. From the above analysis, it is obvious that there is a need to look at the economic perspective of promoting green lifestyle in terms of eco-friendly building construction in rural areas. The Concept of Eco-friendly and Low-cost Housing Eco-friendly and low-cost housing is the concept of building homes using environment-friendly materials and technologies that will reduce the environmental impact through construction activities and effective budgeting techniques and help to reduce the cost of construction. Green and low-cost housing involves proper management of resources in terms of materials, labour or money so that the end product has the lowest cost and, at the same time less environmental impact as a result of the efficiencies that are practiced during planning and construction of these buildings. Approach Following are some of the ways to reduce the construction cost of eco-friendly rural houses: · Efficient use of locally available building materials· Efficient use of locally available waste by-products from stone quarries or other industries for the manufacture of building materials like bricks, concrete blocks, pre cast roofing elements, etc.· Use of precast roofing technologies that do not require any shuttering and take less time for installation or casting of the roof· Efficient structural design of building elements (roof, walls, vertical and horizontal structural members) by avoiding wastage of building materials· Setting up of small and medium scale enterprises for production of eco-friendly building materials using locally available raw materials which also creates livelihood opportunities for the rural population· Creating a proper supply chain of eco-friendly building materials in rural areas· Promoting mass housing construction activities – scaling up of green housing activities· Convergence of Government-supported housing schemes with NGOs’ approach of eco-friendly housing construction activities· Optimum use of space in house design· Ensuring contribution by beneficiary families or house owners in terms of sweat equity while construction of these buildings· Training and capacity building of local masons in green low-cost construction technologies· Close monitoring and supervision while construction of eco housesApplication For over three decades, the Development Alternatives (DA) Group has been promoting eco-friendly and low-cost housing for rural population with the above approach. Following are some of the green low-cost building construction technologies promoted by DA. Rat Trap Bond Masonry Walls Rat trap bond masonry wall ensures that there is an economy in the use of bricks, by making a wall of one brick thickness with fewer bricks rather than a solid English bond wall. This technology has about 25 per cent overall saving on the cost of the building when compared to conventional 9" thick masonry wall construction. The structure has proved its strength for up to three floors with the support of brick columns. With this technique, there is reduction in cost of the wall by 25 per cent over the conventional English bond, where 350 bricks are required per cu m whereas in rat-trap bond only 280 bricks are required and also the reduced number of joints reduces the mortar consumption. Micro Concrete Roofing Tiles for Sloped Roofs Micro-concrete roofing (MCR) technology is able to meet the growing demand for high quality roofing. MCR tiles are a cost-effective and extremely versatile roofing material and can be used in all applications where a sloping roof is required using an appropriately designed under-structure (steel and wood under structure) to make attractive roofs. This technique has been used extensively in cost-effective housing schemes, workplaces, restaurants and poultry farms. Micro-concrete roofing tiles are ideally suited to replace thatch and fired clay tiles in rural areas. A single slope roof MCR roofing costs Rs 90 psf when compared to conventional RCC roof which costs around Rs 250 psf. Plank and Joist Roofing Technology Plank and Joist is a roofing system in which precast RCC slabs and planks are supported over pre-cast RCC beams and joists are placed across the walls. To complete the roof, concrete is then poured over the gaps between the slabs and the beams, which then ties all the pre-cast elements together. This technique can be easily adapted by masons who are familiar with similar techniques of placing stone slabs over girders to construct roofs in rural areas. Pre-casting of roof leads to substantial reduction in construction time and 15 to 20 per cent saving in cost is possible because of the absence of shuttering and reduction in the quantity of steel. Conclusion Eco-friendly construction material and technologies can only be scaled up if they are marketed with the tag or value proposition of low cost as well as structurally sound and aesthetically appealing construction technologies to replace conventional construction technologies. If successfully scaled up, eco-friendly and low-cost housing can lead to more people being able to live in better conditions and can definitely help to improve the quality of life of rural population. q Amol Mangrulkar

|