|

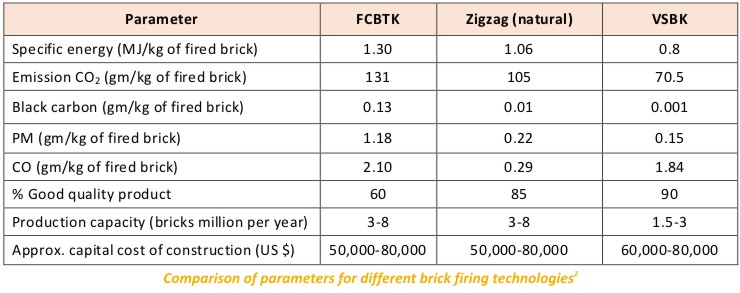

Production of Red Bricks: A Cleaner Pathway The ever-growing population along with rapid industrialisation and urbanisation process demands millions of new buildings and houses every year. This has made construction activity as one of the most flourishing businesses in India and red brick forms the backbone of the construction sector. India is the second largest producer of soil bricks in the world after China. It has more than 125,000 registered/unregistered operating units producing about 250 billion bricks annually (13% of the global production). Indiaís red soil brick industry uses conventional firing techniques, a process which is highly labour intensive and has high amount of fuel requirement1. In India, Bullís Trench Kiln (BTK) is the most common kiln for firing green soil bricks. Previously it was the movable chimney variant with two steel chimneys on an oval base. This technology was modified to the more efficient fixed chimney BTK where the movable chimney has been replaced by various variants of the continuous brick firing technologies. Still there are various issues with the use of the Fixed Chimney BTK technology. The major issue is the environmental concern. The production of bricks using Fixed Chimney BTK consumes lots of energy and creates a large environment footprint. The consumption of coal for the firing of the bricks in FCBTK is very high and it also results in generation of very high amount of CO2 along with black carbon and suspended particulate matter (SPM). In some places, government has banned FCBTK technology which is primarily due to these environment reasons. So, it is quite important to adopt some new technologies replacing the existing firing practices. In this regards, two technologies namely High Draught Kiln (Zigzag kiln) and Vertical Shaft Brick Kiln (VSBK) technologies are becoming very popular as they are more energy efficient and less polluting compared to FCBTK. Between VSBK and Zigzag Kiln, VSBK is more energy efficient and environmentally cleaner. However, capital investment for VSBK is relatively higher compared to Zigzag Kiln which restricts its wide acceptability in medium and large brick enterprises. Incorporation of cheaper fuels in soil bricks, such as coal slurry, coal dust, charcoal dust and sawdust can be used as internal fuels and can help in reducing fuel cost with lower emission. It has been found that a maximum of 5% (by weight) internal fuel can be mixed without compromising the brick quality. Recently TARA has conducted one demonstration trial in Bihar in the month of June 2019 where waste coal has been used as internal fuel. The kiln was Zigzag type (natural draught). Calorific value of the coal dust was 3500 Kcal/kg. The energy and environment assessment has shown that specific energy consumption/brick and average emission level have reduced by approximately 12% and 10% respectively with improved quality of fired bricks after using internal fuel. As a result, overall fuel cost has decreased by nearly 30% which is quite significant.

Undoubtedly, internal fuel-based firing practices are more ecofriendly and energy efficient. In a scientific manner, this technology can be universally adopted for any types of brick kilns. As it consumes the waste coal, it also improves the resource efficiency of the fuel in red brick industries. ■

Endnotes

Palas Kumar Haldar

|