Environmental and Resource

Assessment

for uptake of LC3 in India’s Cement Mix

The Challenge

Globally, cement is the most widely produced material in terms of weight and is a key component in the manufacture of concrete, the second most consumed substance on earth (after water). In an emerging country like India, driven by an increasing demand from construction and infrastructure sectors, the production of cement (and its usage as mortar, concrete etc.) is projected to grow three-fold in the coming decades. Continuation of the business-as-usual scenario would result in an undesirable increase in GHG (particularly CO2) emissions, exploitation of critical natural resources (both as raw materials and fuels) and environmental degradation. This presents an urgent need to explore and adopt viable technological solutions to ensure that socio-economic growth is achieved in an equitable and sustainable manner.

A Possible Solution- Limestone Calcined Clay Cement (LC3)

In recent years, Limestone Calcined Clay Cement (LC3) has emerged as one potentially viable solution in dealing with the looming environmental and resource crisis. LC3 is an innovative cement variety that is composed of a blend of Portland cement clinker, limestone and calcined clay. Typical LC3 cements contain 40% to 65% clinker by weight, 30% to 38% calcined clay, 15% to 20% crushed limestone and 3% to 7% gypsum. It can reduce CO2 emissions by up to 30%, uses lower amount of cement-grade limestone and further utilises low-grade, waste limestone and china clay which are available in abundant quantities. It is also cost effective and does not require capital intensive modifications to existing cement plants. Finally, LC3 can be produced in a similar manner as OPC and PPC by integrating or blending with existing manufacturing equipment, leading to only marginally increased investments for calcining equipment. The pilot production of LC3 (containing a blend of 50% clinker with calcined clay and low-grade limestone) have demonstrated to be quite successful by way of industrial trials conducted in India and Cuba.

Quantification of Future Impacts

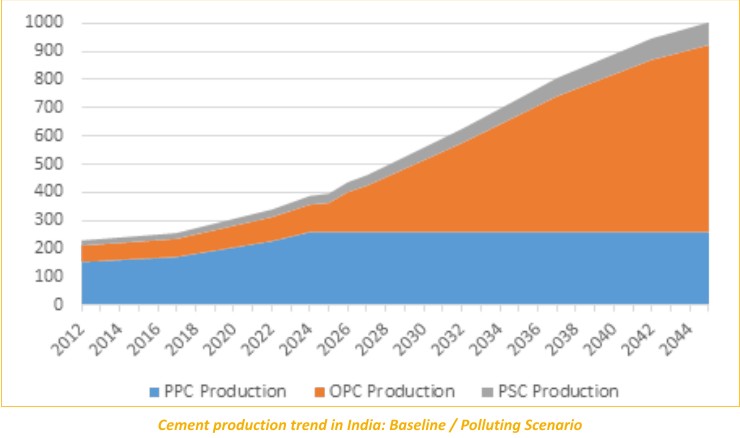

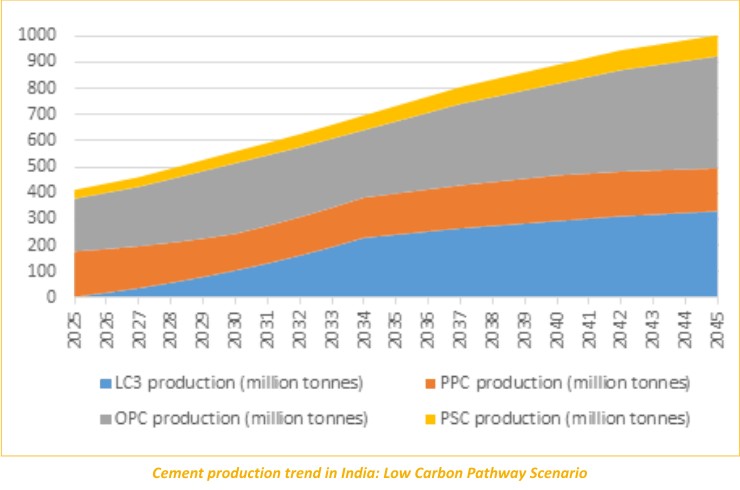

In order to ascertain the net-positive effects due to production of LC3, a comparative analysis of the environmental and resource performance has been carried out between two distinct cement production scenarios, termed as Baseline (BSL) and Low-Carbon Pathway (LCP) scenarios. The BSL scenario (characterised as a ‘polluting’ scenario) envisions sustained production of the traditional cement varieties (namely OPC, PPC and PSC) between the period 2025-2045. However, the LCP scenario foresees the production of LC3 (along with traditional varieties), which is gradually increasing, to ultimately assume a 33% share of the total production mix by 2034.

The cement production trends (between 2025-2045) for both scenarios have been illustrated in figures above.

The investigation reveals that that Low Carbon Pathway scenario performs significantly better in terms of environmental impacts and resource consumption compared to BSL. This is a consequence of the introduction of LC3 which can be seen as a sustainable and viable alternative to the polluting cement varieties.

The results of the analysis reveal the following

benefits of Low Carbon Pathway over Baseline Scenario (between the period

2025-2045):

• Around 1,369 million tonnes of CO2 emissions abated in total (nearly 12%

CO2 savings compared to BSL).

• Cumulative energy savings of around 3,650 PJ, equivalent to conserving 150

million of tonnes coal.

• Total savings in limestone to the tune of 2,850 million tonnes.

• Reduction in average cement-to-clinker ratio from 0.72 to 0.68 over the

entire period.

• Preservation of nearly 31,375 hectares of land (equivalent to the size of

Pune) due to reduction in the amount of waste generation.

■

References:

http://wbcsdservers.org/wbcsdpublications/cd_files/datas/business-solutions/cement/pdf/CementTechnologyRoadmap.pdf

https://www.lc3.ch/

http://energy-transitions.org/sites/default/files/ETC_Consultation _Paper_-_Cement.pdf

Kranav Sharma

ksharma1@devalt.org